leadermac 4-Side Moulder LMC PLANERMAC 450 mm Width Un-Jointed

leader mac4-Side Moulder LMC PLANERMAC 450 mm Width Un-Jointed

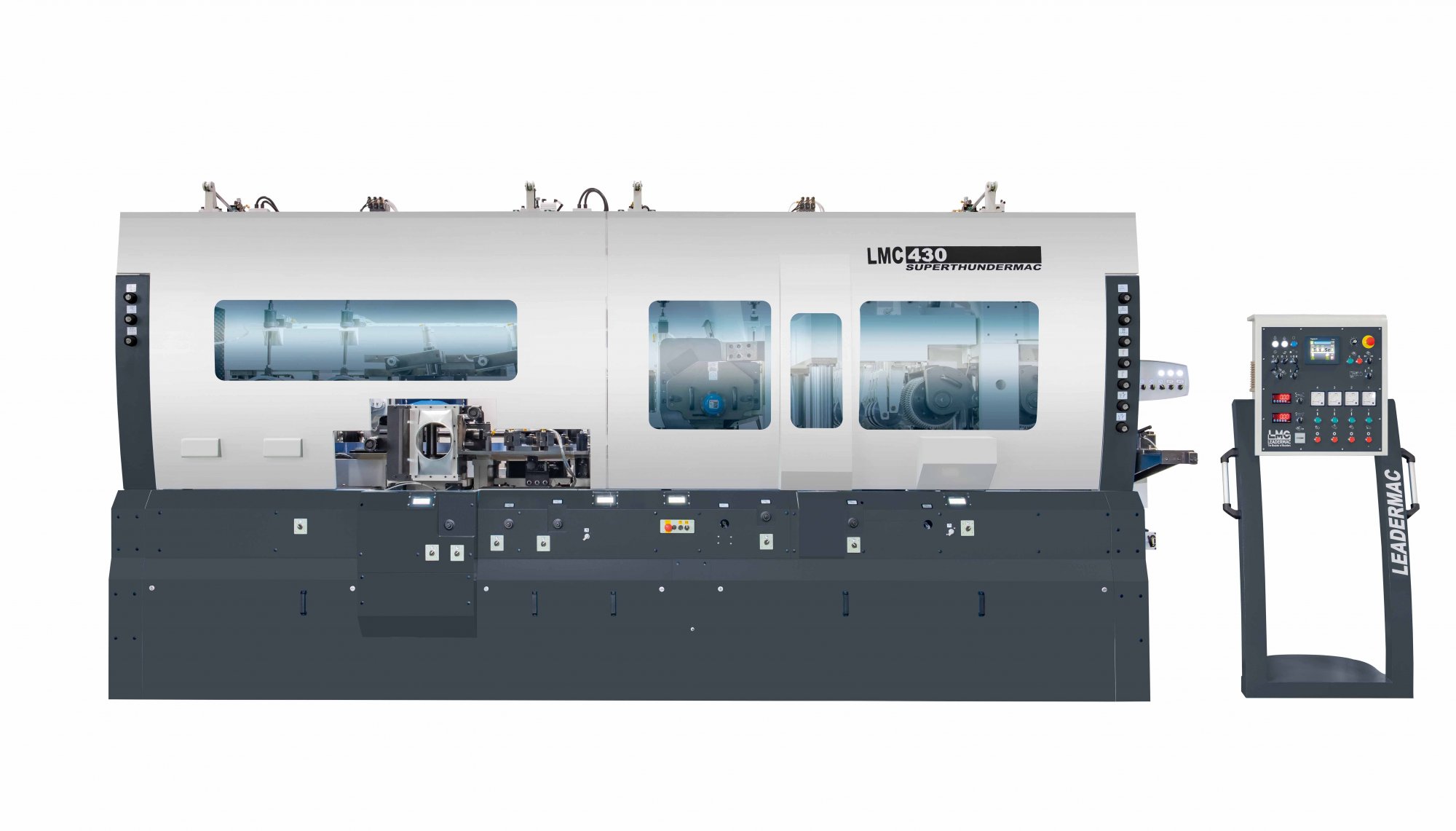

- Moulders with CE certification.

- One-piece, Extra Heavy Cast Iron or Steel machine frame is specially heat treated for

- Programmable controller provides convenient width and depth of cut setting.

- The full safety enclosure serves as a chip guard and helps to reduce noise.

- Pneumatic pressure of the feed rollers can be easily set to provide an outstanding feeding effect.

- Table surface is hard-chrome plated for maximum wear resistance.

- One-piece, steel iron machine frame is specially heat treated for maximum stability and rigidity.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- The smooth initial feeding of stock is achieved by means of independently pneumatic feed rollers.

Centralized Control Panel

Width and depth of cut setting can be accurately and conveniently made through digital controllers on the control panel.

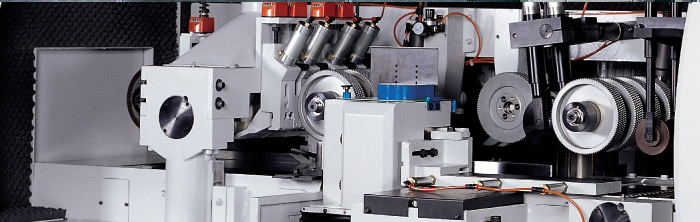

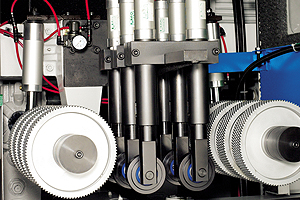

Pneumatic Feeding Rollers

The feed rollers are pneumatically loaded for excellent feeding effect. 3 stage, feed roller pressure setting.

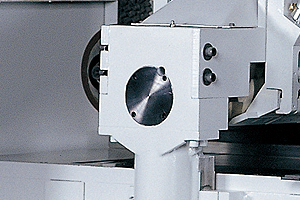

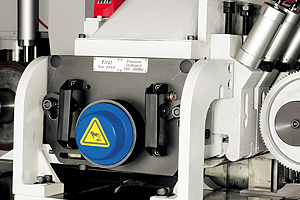

Outboard Bearing for Cutterhead (Std.)

The first bottom and top cutterheads are supported by additional outboard bearings, providing a solid support.

Pneumatic Control Pressure Rollers

Specially designed 6 pneumatically controlled pressure rollers provided on the first bottom spindle assure maximum smoothness for work feeding and perfect surface bottom finish.

ENLARGED OUTBOARD BEARING FOR CUTTERHEAD (OPTIONAL)

The first bottom cutterhead and final spindle are supported by additional hydro outboard bearings providing a solid support. The enlarged hydraulic bearing supports also provide convenient cutterhead change by pulling it out.

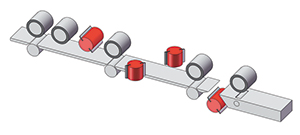

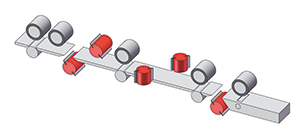

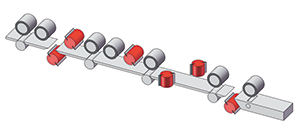

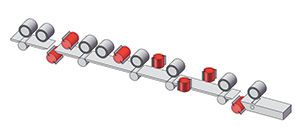

A Wide Range of Spindle Configurations (other configurations available on request)

|

LMC-445 4-SPINDLE |

LMC-545 5-SPINDLE |

LMC-645 6-SPINDLE |

|

LMC-745 7-SPINDLE |

LMC-845 8-SPINDLE |

| LMC-245PL to LMC-11106PL | Standard Base Equipment | Available Options |

| Number of Spindles, min-max | 2 to 11 | Special Machine Configurations on request |

| Worbng Width (at a tool cutting circle of 125mm-200mm) | 15~450mm (0.59"~17.7") | 500mm (20") ; 600mm (24") ; 900mm (36") ; 1065mm (42") |

| Working Thickness (at a tool cutting circle of 125mm-200mm) | 10~200mm (0.39"~7.1") | to 200mm (8") ; to 250mm (10") ; to 300mm (12") ;or to 350mm (14") |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 11 KW / 15HP | to 75KW (100HP) |

| Spindle Speed | 5500 RPM | 6000 RPM or 7200 RPM |

| Spindle Diameter | 50mm (2") | 1 13/16" or 2 1/8" |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 125~180mm (5"~7.1") | |

| Tool Cutting Circle, Vertical Spindles, Left, min-max | style="background-color: rgb(248, 248, 248);"125~200mm (5"~8") | to 250mm (10") |

| Tool Cutting Circle, Vertical Spindles, Right, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Feed Motor | 3.7 KW / 5HP / INVERTER | to 15kw (25 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 6~24 m/min (20~80FPM) | to 36mpm (120fpm) ; 48mpm (160fpm) ; 60mpm (200fpm) or 90mpm (300fpm) |

| Top Feed Roller Diameter | 200mm (8") | |

| Top Feed Roller Width | 4 x 50mm (2") | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for infeed table and edge-jointing fence | 10mm (0.4") | |

| Adjustment range for vertical spindle (axial) | 40mm (1.57") | |

| Adjustment range for horizontal spindle (axial) | 20mm (0.78") | |

| Length of the Infeed Straightening Table | 1.4M (55") | 1M (39") ; 2M (78") ; 2.5M (98") or 3M (120") |

| Mechanical digital readouts for the pressure shoes & hold-down unit | Included | |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Motorized vertical adjustment of Feed Beam | Included | |

| Pneumatic Lateral Pressure Roller System opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | |

| Quick Set Setworks on Near Side Head (s) & Top Heads (Radial Set) | Included | optional on all Axis and SmartSet Controls as noted Below optional |

Related Product

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map