Identifying 3 prominent SCM machine groups

As one of the leading manufacturers of woodworking machinery and solutions, SCM machines always bring customers the best quality products, speed, and performance. So do you know the top 3 prominent SCM machine groups? Specifically, how much do SCM machines cost? Let's find out now!

1. SCM sliding table saw

The most prominent SCM machine group is the sliding table saw. SCM sliding table saws meet all possible configuration needs, from the widest to the simplest, adapting to every level of use. This is a tool used to cut straight on various materials, including wood and its derivatives, plastics, metals, and more.

Not many people know that it was invented by the carpenter Walter Taylor in 1775. At that time, when this type of machine only produced straight cuts, with high cutting progress but poor precision and surface finish, the sliding table saw was born and developed, managed to achieve high-quality production.

Thanks to the high-tech level of the SCM sliding table saw, even first-time users with little experience working with sliding table saws can achieve excellent results.

Moreover, thanks to the different devices specially designed for the SCM sliding table saw, not only straight cuts can be achieved but also high-precision angle cutting without complex mathematical calculations (different devices for cutting angles).

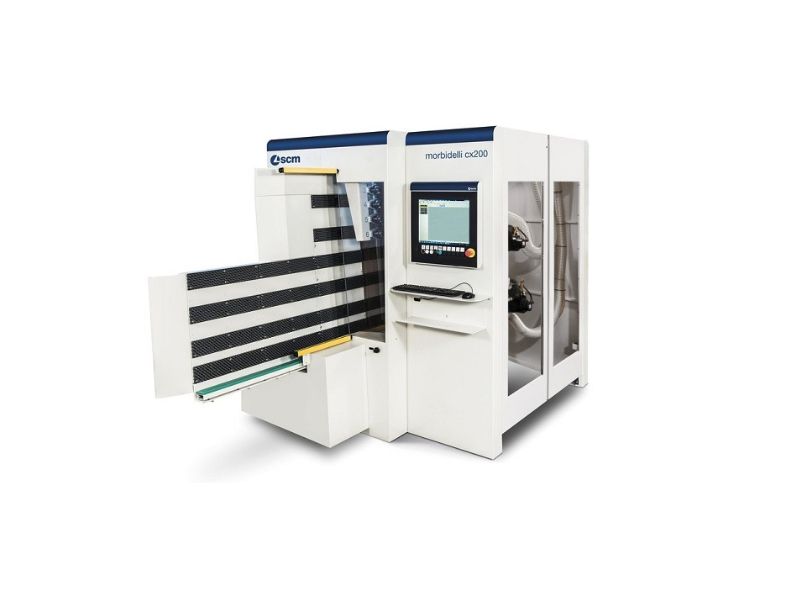

2. SCM Morbidelli CX200 CNC center drilling machine

The outstanding SCM machines include the SCM Morbidelli CX200 CNC center drilling machine. This CNC drilling center is used to drill various materials, applicable in manual or industrial wood processing, by rotating the drill head in contact with the block and static hole. SCM machines provide different solutions for CNC drilling centers to adapt to both manual and industrial processing.

The product is designed for small and medium sized wood processing workshops, but also for larger companies that produce custom products, with in-house prototype development departments. Thanks to 8 independent vertical axes, 6 horizontal axes, and a "X" blade, there is a machine version with a routing set. Notable advantages of SCM machines include:

- Machine setup based on control panel size.

- Top performance with minimal running and processing operations, with a spindle speed of 40m/min.

- With a total size of 5m2, it can be installed in small spaces.

- The machine is easy to use and suitable for any investment capability.

- The upper control panel operating unit allows for very precise and clean work. In addition, any imperfections in the thickness of the control panel are hidden inside the furniture (out of sight).

- Maximum flexibility: The machine version with a routing set has a 5.5 kW spindle motor suitable for any processing work.

- Fully automatic: thanks to the automatic surface alignment device, the control panel is loaded into the machine and restored after the milling program is finished, without any other intervention from the operator.

- The SCM machine software allows for the creation of projects and geometric drawings to be automatically converted into drilling routing programs for the machine.

3. SCM Olimpic K-560 TER2 Automatic Edgebanding Machine

Finally, the most outstanding product line of SCM machines cannot miss the SCM Olimpic K-560 TER2 automatic edgebanding machine. This product possesses:

- High performance and flexibility: Olimpic K-560 TER2 is designed for companies that require processing many boards per day even though they may differ. The product has some solutions to ensure the best processing on any type of control board.

- Perfect bond with "SGP" glue thanks to perfect quantification and special roller spreader. Using EVA and Polyurethane glue can be achieved thanks to the plasma anti-adhesion treatment process, quick and easy glue replacement.

- Superior finishing quality with AirFusion+ technology allows edge banding without glue, ensuring that the joint between the edge and the control board is invisible.

- Perfect results on all surfaces. The controlled axes allow all intermediate positions of the cutting and edging groups, ensuring optimal edge range even in cases of different surface roughness or boards covered with protective film. These units allow processing of 2 different radii, infinite thin edges, and solid wood.

- "Round X" rounding unit with productivity and quality using 2 motor technology. The features of the device allow performing the dual function of cutting and rounding simultaneously. Two common operations in a single group require less space and with a working distance between boards of only 600 mm, helping to reduce time for edge range.

With the above information, we hope you have gained information about the top 3 most outstanding SCM machines today. If you need detailed advice on product lines as well as the exact SCM machine price, please contact us via the hotline number!

Other news

- What is SCM? What are the benefits of SCM's machines in large-scale wood production? (17/03/2023)

- Important Considerations When Choosing an Unisand Sanding Machine for Your Project (10/03/2023)

- What makes the Schone paint roller machine an important product in the wood processing industry? (06/02/2023)

- Is Schone UV dryer worth investing in? (22/12/2022)

- Compilation of necessary information about the IR Schone drying machine (20/12/2022)

- The elements that make up the quality of Schone polishing machines (19/12/2022)

- Review of the advantages of the Schone dust brush machine (02/12/2022)

- Leadermac wood planers are at the top of the market (01/12/2022)

- Highlights of SCM CNC central machine (24/11/2022)

- Genuine SCM woodworking machines make the name of SCM (23/11/2022)

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map