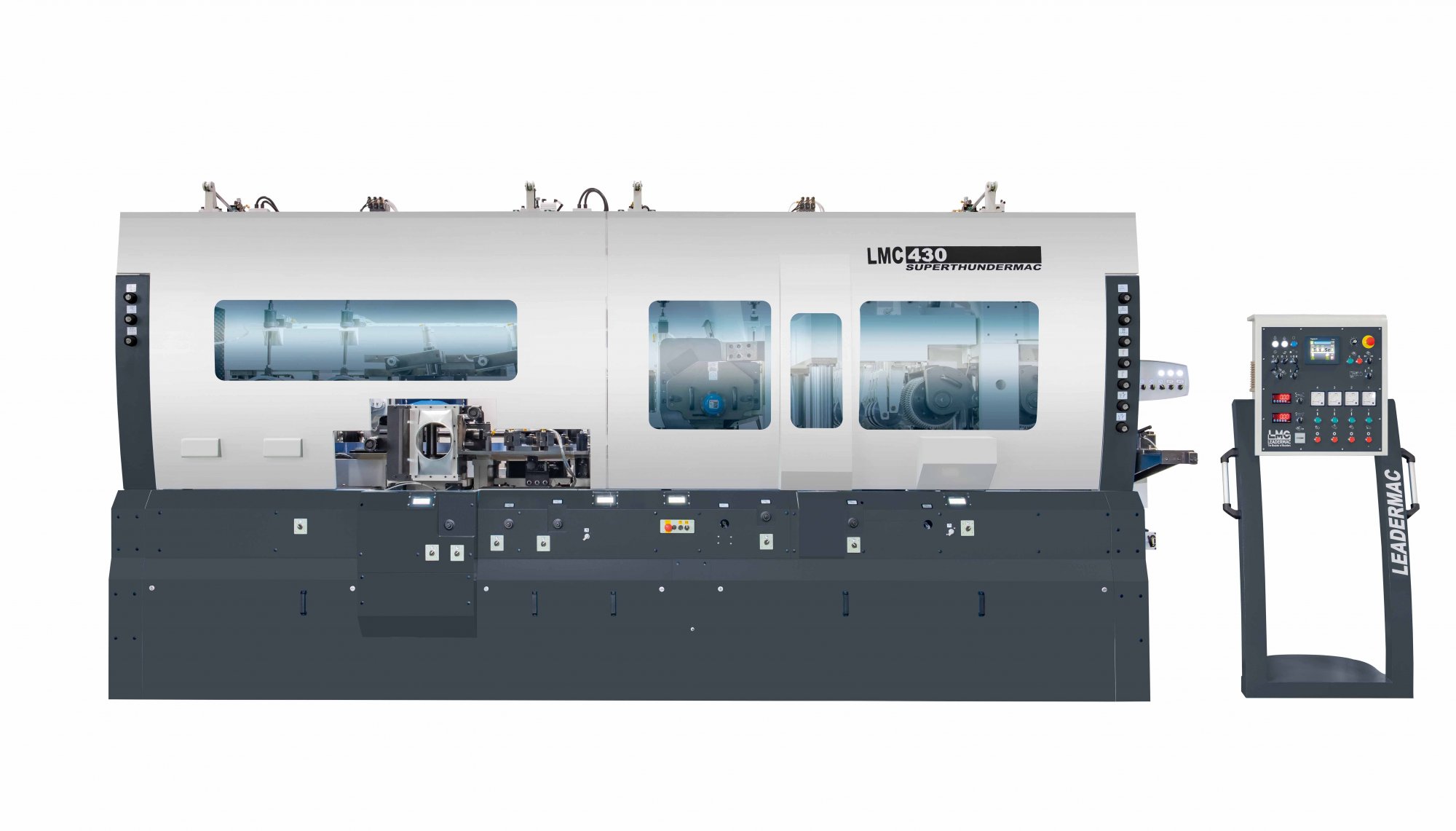

leadermac 4-SIDE MOULDER LMC COMPACT 24 m/min

leadermac LMC COMPACT 24 m/min Moulder

- All moulders awarded CE certification.

- 1-piece, Cast Iron Machine Frame is specially heat treated for maximum stability and rigidity as standard configuration.

- Faster Feed Speeds of up to 24 meters a minute(80 fpm) are standard.

- Programmable Controller – REC Setworks provide convenient depth of cut settings.(Optional)

- Adjustment of each spindle can be easily performed by using the front adjustment levers.

- Each spindle is driven by an individual motor for powerful drilling and easy control.

- Pneumatic Pressure of the top feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces are hard-chrome plated for maximum wear resistance.

- All manually adjusted turning parts are housed in permanent grease lubricated bearings for oil-free lubrication.

- The Full Safety Enclosure serves as a chip and piece guard and helps to reduce noise

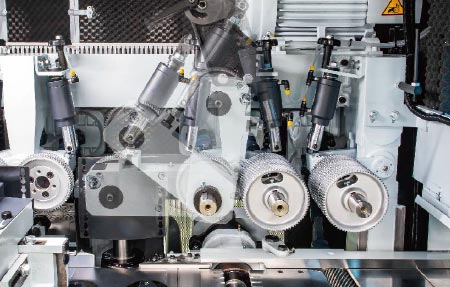

Extremely Short Feeding Capability

The cutting heads are specially designed so that there is a uniquely short distance between them. This results in a superior moulding finish.

6,000 RPM (7,200 RPM- optional) high speed spindles with Inverter (VFD) controlled Feed Motor with LED display, Feeding speed up to 24 m/min (80FPM).

Accurate Pressure Display

The position of the Top Head Chip Breakers and Pressure Plates are accurately displayed by digital counters. This increases cutting stability.

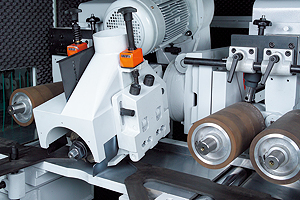

Liftable Auxiliary Feed Roller

The short stock powered feed mechanism provides added smoothness for short workpiece feeding. The auxiliary feed rollers are power driven for effortless feeding effect, and are quick-liftable for convenient cutterhead change or setup.

Powered Infeed Bottom Roller

Powered Infeed Bottom Roller (actually More Powered Top & Bottom Feed Rolls than almost all of our competition.) The smooth initial feeding of the stock is achieved by means of the independently powered infeed rollers.

Short Stock FeederThis device permits the feeding of short stocks with a minimum length of 8". The short stock feeder is driven by a gear drive unit for a powerful and smooth effect.

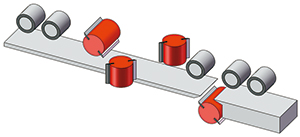

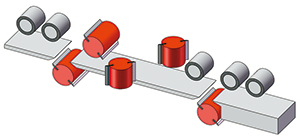

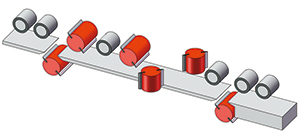

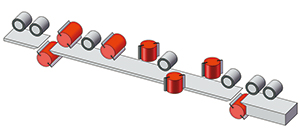

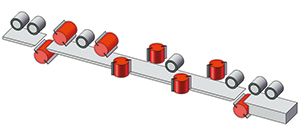

A Wide Range of Spindle Configurations (other configurations available on request)

|

LMC-423 4-SPINDLE |

LMC-523 5-SPINDLE |

LMC-623 6-SPINDLE |

|

LMC-723 7-SPINDLE |

LMC-823 8-SPINDLE |

| LMC-123C to LMC-823C | Standard Base Equipment | Available Options |

| Working Width (at a tool cutting circle of 125mm) | 15-230mm (0.59"-9.1") | to 260mm, 300mm (10.2", 12" optional) |

| Working Height /Thickness (at a tool cutting circle of 125mm) | 10-150mm (0.39"-6") | to 6mm & to 200mm (to 1/4" & to 8" ) - optional |

| Number of Spindles, min-max | 1 to 8 Heads / Spindles | All different types of Spindle Configurations - optional |

| Basic motor Capacity of Feed - Variable Speed Drive | 4KW / 5HP | 5.5KW/7.5HP or 7.5KW/10HP - optional |

| Feed Speeds, Infinitely Variable | 6 - 24 m/min (20 - 80 fpm) | |

| Basic Motor Capacity Per Spindle | 7.5KW / 10HP Vert & 11KW/15HP Hor. | up to 18.5KW/25HP - optional |

| Spindle Speed | 6000 RPM | 7200 RPM - optional |

| Spindle Diameter | 40mm (1.6") | 50mm, 1 1/2", 1 13/16" |

| Tool Cutting Circle, 1st Bottom Spindle, Min-max | 125-160mm (4.9"-6.29") | |

| Tool Cutting Circle, Vertical Spindle(s), Left, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Vertical Spindle(s), Right, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Horizontal Spindles, Top, Min-max | 112-200mm (4.4"-7.9") | |

| Tool Cutting Circle, Borizontal Spindles, Bottom, Min-max | 112-200mm (4.4"-7.9") | |

| Feed Roll Diameter | 140mm (5.5") | |

| Top Feed Roll Width - Each Roll With Multiples on all Top Shafts | 50mm (2") | |

| Bottom Feed Roll(s) Width | Full Width | |

| Pneumatic Pressure for Feed Rolls, Max | 6 bar (85psi) | |

| Adjustment Range for Infeed Table | 10mm (0.4") | |

| Adjustment Range for Edge-jointing Fence | 10mm (0.4") | |

| Adjustment Range of Vertical Ppindles (axial) | 40mm (1.58") | 80mm (3.14") - optional with setworks if desired |

| Adjustment Range of Horizontal Spindles (axial) | 20mm (0.79") | |

| Length of the Infeed Straightening Table (Bottom Head Cut) | 2M (78.7") | 1.5M, 2.5M or 3M (58", 98" or 120" - optional) |

| Diameter of Dust Hood for Vertical Spindle (s) | 125mm (5") | |

| Diameter of Dust Hood for Horizontal Spindle (s) | 125mm (5") | |

| Chainless Cardan Shaft Feed System w/ HD Gearboxes | Standard | |

| Motorized Vertical Adjustment of Feed Beam | Standard | |

| Lateral Pressure Rollers Opposite First Right Spindle | Spring Tensioned Standard | Pneumatic Tensioned - optional |

| Sectional Radial Lift - Linkage Style Top Head Chipbreakers | Spring Tensioned Standard | Pneumatic Tensioned - optional |

| Mechanical Digital Readouts for the Pressure Shoes & Hold-down Unit | Standard | Metric or Inch Readouts |

| Mechanical Digital Reaouts on all Spindle Axis | Single - Std. | Dual on Near Side, & Tops - Radial Readouts & Quik Set - optional |

| Central Location of all Lubrication Points Along the Front of the Machine | Standard | |

| Mechanical Digital Readouts for the Pressure Shoes & Hold-down Unit | Standard | Metric or Inch Readouts |

| Mechanical Digital Reaouts on all Spindle Axis | Single - Std. | Dual on Near Sdie, & Tops - Radial Readouts & Quik Set - optional |

| Central Location of all Lubrication Points at the Front of the Machine | Standard | |

| Table Lube System | Manual 1 shot | Auto Electronic - Timer Controlled - optional |

| Full Sound and Safety Enclosure | Standard |

Related Product

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map