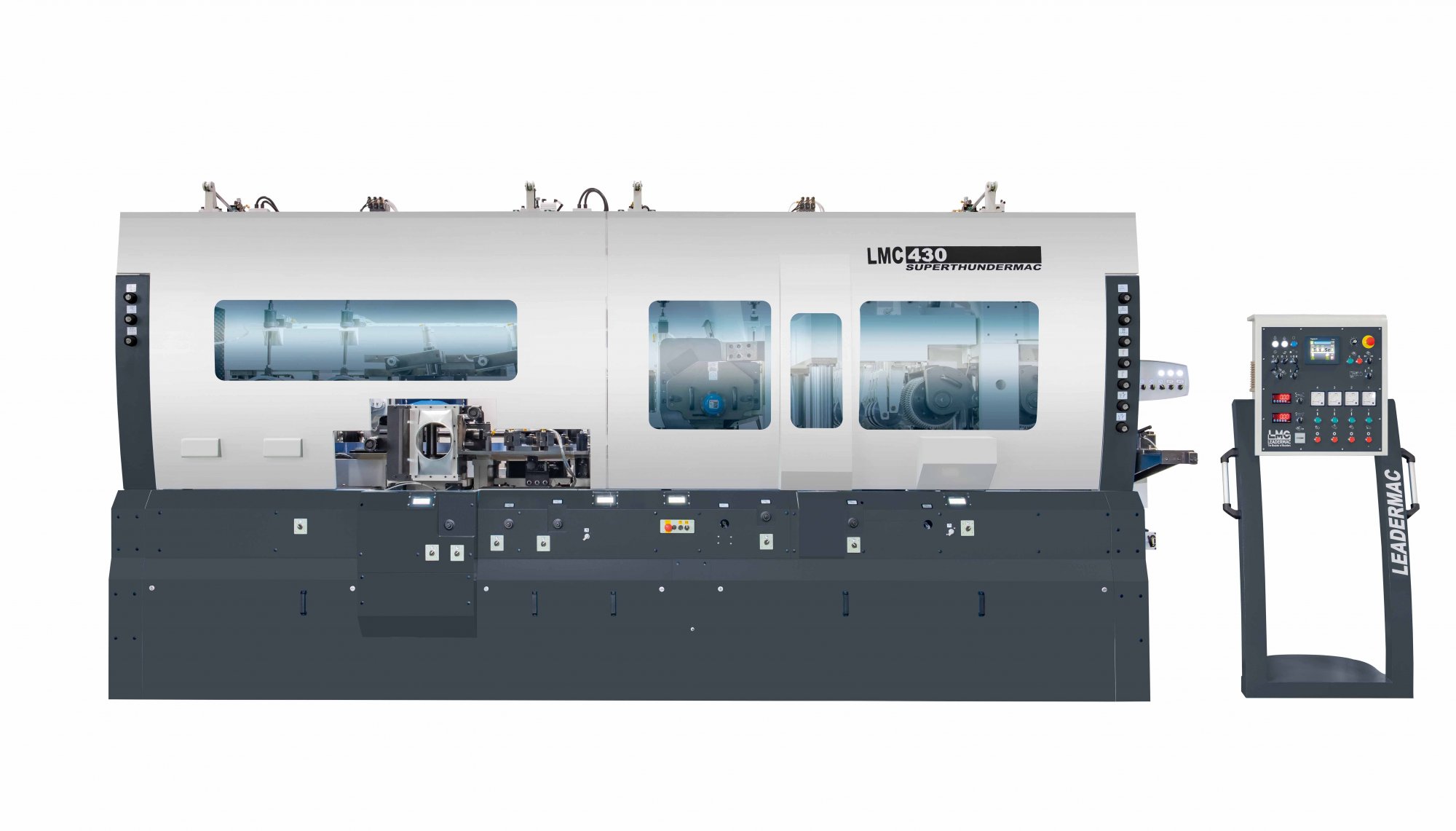

Leadermac 4-Side Moulder LMC SMARTMAC Frame

Advantage

Leadermac LMC SMARTMAC Frame Moulder

- It's a Powerful, Precise, Efficient and Economical Machine in One Small Package.

- 1 piece, Cast Iron Machine Frame is specially heat treated for maximum stability and rigidity (std. machine configurations).

- Infinitely variable Feed Speeds up to 24 mpm (80fpm) are standard.

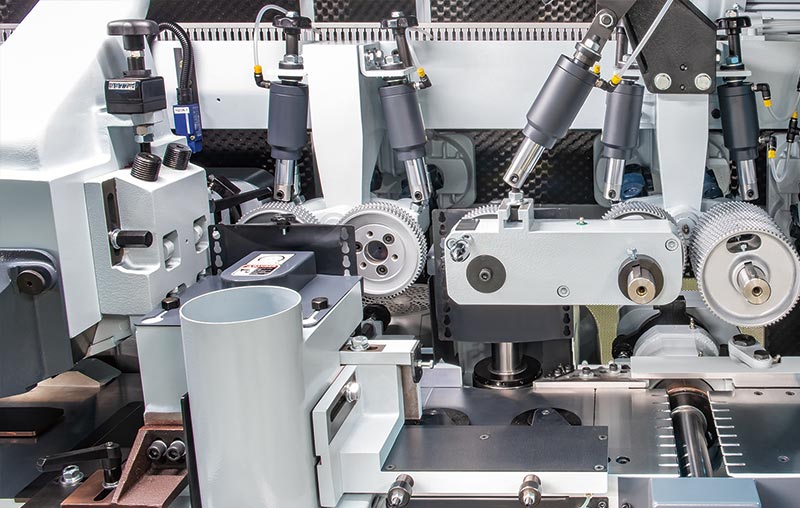

- Adjustment of each spindle can be easily performed using the front of the machine adjustment

- Pneumatic pressure of the feed rollers can be easily set to provide an outstanding feeding effect (Infeed, Midfeed & Outfeed Top Rolls separate settings).

- All Bed Plates(except Btm Head Receiving Table - Special Hard Tool Steel), Guides, Chip Breaker shoes & Pressure Plates are hard-chrome plated for maximum wear

- resistance.

- All lubrication points located at front of machine (central blocks colour coded).

- 1 Shot Bed Lubrication - std.

- Increased horsepower available. (optional)

- Programmable Setworks Control for convenient thickness of cut settings. (optional)

- The full Safety Enclosure (Heavy Gauge Steel) serves as a chip guard and helps to reduce noise.

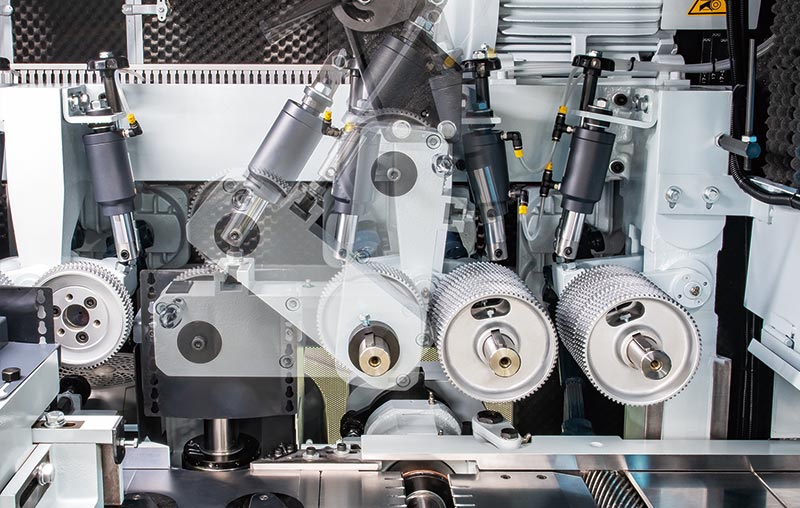

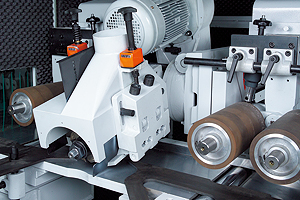

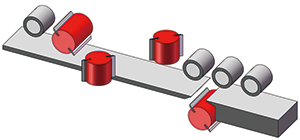

Liftable Auxiliary Feed Roller

The mechanism provides added smoothness for short workpiece feeding. The auxiliary feed rollers are power driven for effortless feeding, and are liftable for convenient cutter change or setup.

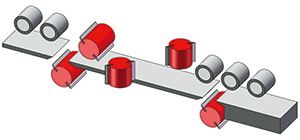

Side Pressure Wheels for Third Spindle

Provides positive feed effect for short and narrow stock.

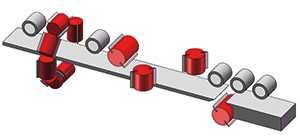

Universal Spindle (LMC-423S & LMC-523S)

The universal spindle can be operated horizontally, vertically or at any angle in between. Powered universal spindle horizontal elevation provides quick set-ups.

Standard Infeed Table Length - 2 meters (78").

A Wide Range of Spindle Configurations (other configurations available on request)

LMC-423

4-SPINDLE

LMC-523

5-SPINDLE

LMC-523S with universol spindle

5-SPINDLE

Technical data

| LMC-223P to LMC-823P | Standard Base Equipment | Available Options |

| Working Width | 15-230mm (0.59"-9.1") | to 180mm (7") - optional (LMC 418S/518S) |

| Working Thickness | 10-125mm (0.39"-4.9") | to 150mm (6") - optional |

| Number of Spindles, min-max | 4 or 5 Spindles | 1 to 5 Spindles & Universal - optional |

| Base/Std. Motor Power per Spindle / - 1st Bottom (5.5KW/7.5HP) | others 7.5KW / 10HP | to 15HP optional |

| Spindle Speed | 6000 RPM | 7200 rpm - optional |

| Spindle Diameter | 40mm (1.6") | 1 1/2", 1 13/16" - optional |

| Tool cutting circle, first bottom spindle, min-max | 125-160mm (4.9"-6.3") | |

| Tool cutting circle, vertical spindles, left, min-max | 112-180mm (4.4"-7.1") | |

| Tool cutting circle, vertical spindles, right, min-max | 112-180mm (4.4"-7.1") | |

| Tool cutting circle, horizontal spindles, top, min-max | 112-200mm (4.4"-7.8") | |

| Tool cutting circle, horizontal spindles, bottom, min-max | 112-200mm (4.4"-7.8") | |

| Feed motor | 3KW / 4HP | |

| Feed Speeds, infinitely variable | 6-24m/min (19.5-80fpm) | |

| Feed Roll - Diameter | 140mm (5.5") | |

| Feed Roll - Width - Top Rolls | 50mm (2") each | Rolls are stacked on Shafts |

| Feed Roll - Width - Bottom Roll (s) | Full Width | |

| Pneumatic / Air Pressure for feed rolls, max | 6 Bar (85psi) | |

| Adjustment range for Infeed Table and Edge-Jointing Fence | 10mm (0.4") | |

| Adjustment range of vertical spindles (axial) | 20mm (0.8") | |

| Adjustment range of horizontal spindles (axial) | 20mm (0.8") | |

| Length of the straightening table | 2M (78.7") | 2.5M (98") & 3M (120") - optional |

| Diameter of dust hood for vertical spindle | Ø125mm (5") | |

| Diameter of dust hood for horizontal spindle | Ø125mm (5") | |

| Sectional Top Head Chipbreaker | Spring Tensioned - Std. | Pneumatic- optional |

| Chainless HD Cardan Shaft Feed System | Std. | |

| Mechanical Digital Readouts for All Head Axis, Top Head Chip Breakers & Pressure Shoe | Std. | |

| Full Sound and Safety Enclosure with Srobless Lighting | Std. | |

| Motorized vertical adjustment of Feed Beam | Std. | |

| Lateral pressure Dual Rolls opposite first right spindle | Std. | Pneumatic - optional |

Video

Customer reviews

Related Product

Vetta Head Office

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

Vetta showroom- Binh Duong branch

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map