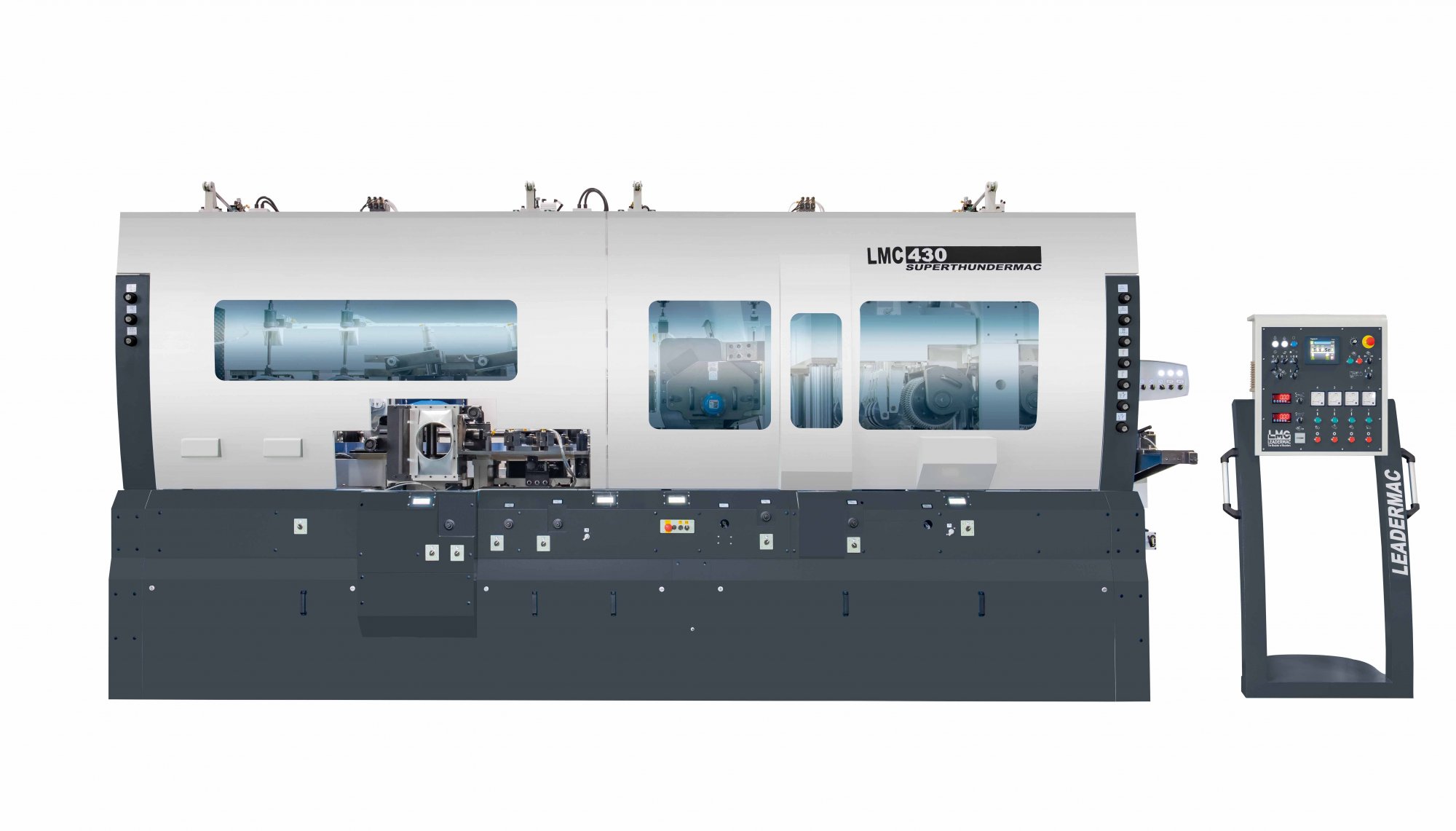

Leadermac 4-Side Moulder LMC THUNDERMAC 80~150 m/min Jointed Moulder

Leadermac 4-Side Moulder LMC THUNDERMAC 80~150 m/min Jointed Moulder

- All moulders with CE Certification if desired.

- Faster feed speeds of up to 80 meters a minute (265 fpm) are standard - to 185 mpm (610fpm) - optional.

- Programmable Controller provides convenient thickness and width of cut settings.

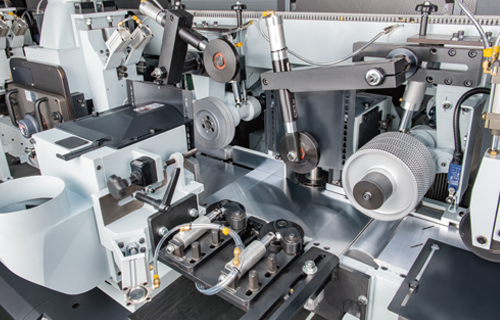

- Adjustment of each spindle can be easily performed using the front of the machine adjustment ·Exclusive, separate adjustment of the vertical spindles and the support tables allows the tables to be positioned extremely close to the cutterheads for added cutting stability.

- The full safety enclosure serves as a chip guard and helps to reduce noise and is equipped with Strobe Free Lighting.

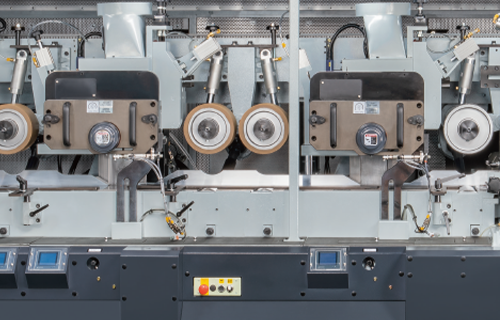

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- Multiple pneumatic pressure of the feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces, guides, chip Breaker shoes and Pressure plates are hard-chrome plated for maximum wear resistance.

- All manually adjusted & turning parts are housed in dry grease lubricated bearings for oil-free lubrication.

- Automatic lubricator is provided to supply oil to the feed tables.

- One-piece, Extra Heavy machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

- The powered Top & Bottom Full Width outfeed rolls provide stable and smooth workpiece outfeed even for especially thin or smooth materials. The rolls remain perfectly parallel even after long-term use.

- Mechanical digital Readouts for all head axis and pressure elements & Chip Breaker Shoes and Pressure Plates of the Top spindle(s).

- Sectional Chip Breaker Assembly in front of top spindle(s).

- Motorized vertical adjustment of the top spindle including PC Setworks & Digital Readouts.

- Finest Alloy Steel Spindles and housings with 2 sets of Ultra Precision Duplex Bearings in each spindle. All are permanently grease lubricated.

- All horizontal Spindles outfitted with Quick Loc Hydro-loc Outboard Bearings and Cutterhead supports.

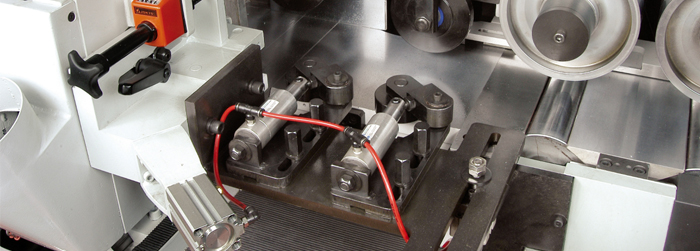

- Built in Straight & Profile jointers provide accurate operation with high quality finish.

- The full Safety Enclosure is heavy gauge steel & serves as a chip guard and helps reduce noise.

- It is equipped with Strobe Free Lighting.

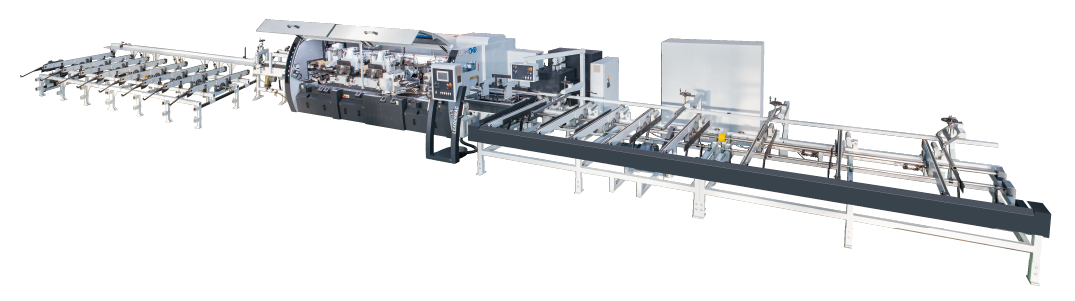

FULLY AUTOMATIC FEEDING SYSTEM (Optional)

When the system detects the workpiece on the infeed chains, the hydraulic feed system will pneumatically lower and activate the top roller to feed the workpiece into the machine. This provides constant and stable feed, reducing labor requirements and decreasing cycle time.

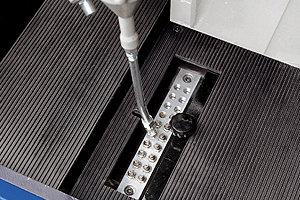

CENTRALIZED LUBRICATION POINTS

Greasing to all critical parts is conveniently made by the centralized arrangement of lubrication points.

CONVENIENT SPINDLE ADJUSTMENT

Adjustment of all spindles is easily done from the front. The adjustment points are all at the same height, for more convenient and faster adjustment.

FULLY AUTOMATIC FEEDING SYSTEM (Optional)

When the system detects the workpiece on the infeed chains, the hydraulic feed system will pneumatically lower and activate the top roll to feed the workpiece into the machine. This provides constant and stable feed, reducing labor requirements and decreasing cycle time.

DESIGNED FOR PARAMOUNT STABILITY

Powerful, heavy-duty pneumatic side and pressure shoes for the left spindle provide extremely stable pressure for high-speed operations. A pneumatic Top Pressure Roller System in front of the right vertical spindle ensures constant stock feed.

POWERED INFEED ROLLER

The smooth initial feeding of the stock is achieved by means of the independently powered Top & Bottom Infeed Rolls.

SELF ACTUATING CLUTCH TYPE FIRST TOP FEED ROLL

The first feed roll (with Built in clutch) is powered, but with high speed infeed, the roll will run freely, eliminating potential damage to the workpiece and machine. This allows for smooth operation with exceptionally high feed speeds.

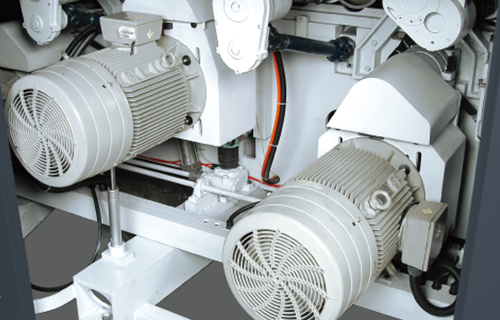

HEAVY DUTY GEARBOX & MOTOR

The feed rollers are driven through a combination of universal shafts and gearboxes, ensuring no loss of power transmission. A smooth feeding effect is assured. Heavy duty gearboxes have no backlash and provides powerful and accurate feeding performance.

FEED SYSTEM

The infeed rolls work in conjunction with a limit switch (anti double-up gate) to stop the machine feed if the workpiece is too thick or there is double up

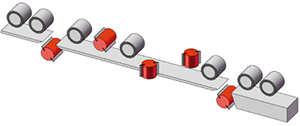

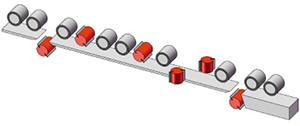

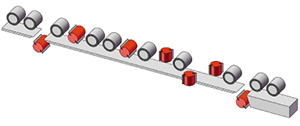

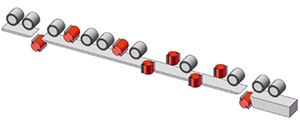

A Wide Range of Spindle Configurations (other configurations available on request)

|

LMC-523 5-SPINDLE |

LMC-623 6-SPINDLE |

LMC-723 7-SPINDLE |

|

LMC-823 8-SPINDLE |

LMC-923 9-SPINDLE |

LMC-1023 9-SPINDLE |

| LMC 223T to LMC 1123T or LMC 230T to LMC 330T: | Standard Base Equipment | Available Options |

| Number of Spindles (Min - Max) | 2 to 11 | |

| Working width (with a head cutting circle of 163mm) | 20~230mm (0.78"~9.1") | |

| Working Thickness (with a head cutting circle of 163mm) | 10~150mm (0.39"~6") | 260mm (10.2") or 300mm (12") |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 17.5 7 22 KW / 20 & 30HP | to 200mm (8") |

| Spindle Speed | 6000 RPM | to 45KW (60HP) |

| Spindle Diameter | 50mm or 1 13/16" or 2 1/8" | 7200 RPM or 8000 RPM |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 160~260mm (6.3"~10.25") | |

| Tool Cutting Circle, Vertical Spindles,min-max | 160~260mm (6.3"~10.25") | |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 160~260mm (6.3"~10.25") | |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 160~260mm (6.3"~10.25") | |

| Feed Motor - Standard | 15 KW / 20HP | |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 8-80 m/min (25~265FPM) | to 30kw (40 HP) |

| Top Feed Roller Diameter | 205.36mm (8") | 120m/min (400FPM), 160m/min (533FPM) |

| Top Feed Roller Width | 3 x 50mm (2") | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for Infeed Table and edge-jointing Fence | 10mm (0.4") | |

| Adjustment range for Vertical Spindles (axial) | 80mm (3.2") | |

| Adjustment range for Horizontal spindles (axial) | 40mm (1.6") | |

| Length of the Infeed Straightening Table | 0.8M (32") | |

| Clutch Roll on 1st top Infeed Roll | Included | |

| Digital Readout and Quick Set to Main guide & Infeed Rolls(Btm Head Cut-table) | Included | |

| Quick Set Setworks on Near Side Head(s) & Top Head(s) (Radial Set) | Included | |

| Mechanical Digital Readouts for the Spindles, Top Head Chip Breakers | Included | |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | |

| Motorized vertical adjustment of Feed Beam with Top Feed Rolls | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Pneumatic Lateral Pressure Roller Systems on Infeed & opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | |

| Diameter of Dust Hood for Vertical Spindles | Ø200mm (7.9") | optional on all Axis and SmartSet Controls as noted Below optional |

| Diameter of Dust Hood for Horizontal Spindles | Ø230mm (9.1") |

Related Product

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map