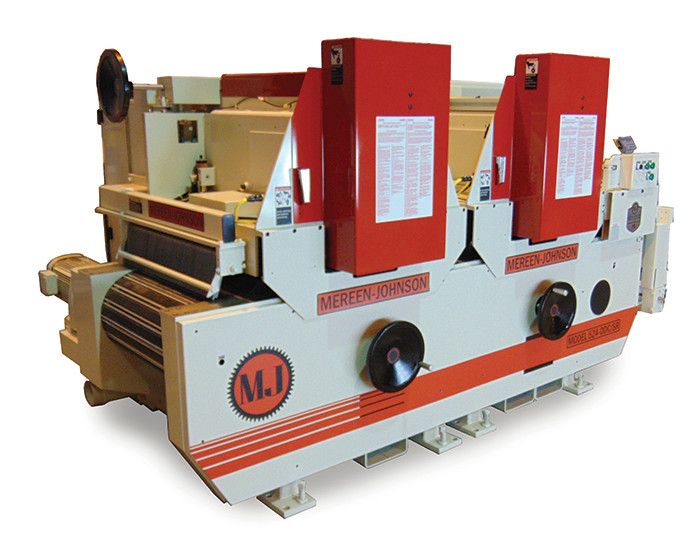

Model 312 and 521 DC-SR Select-A-Rip Straight Line Multiple Rip Saw

Model 312 and 521 DC-SR Select-A-Rip Straight Line Multiple Rip Saw

The ultimate in production flexibility, reliability, accuracy, performance and value

More choices to meet your specific production requirements, including:

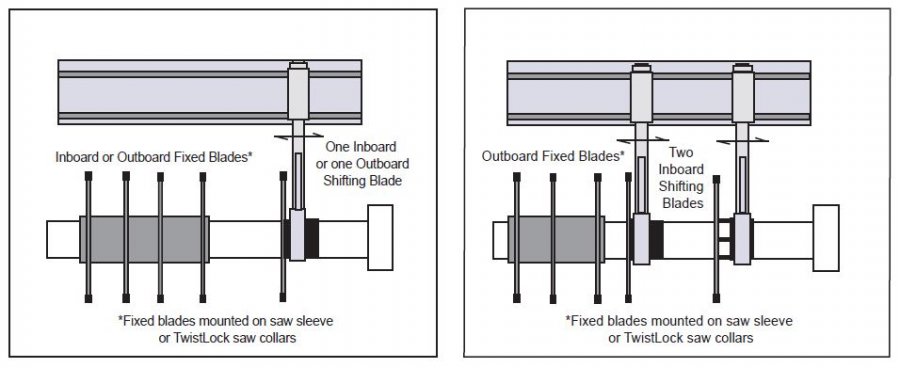

- Our Model 312-DC/SR Series for big ship performance at a small shop price - 12" arbor capacity with up to two inboard shifting saws to facilitate access to outboard mounted TwistLock fixed blade saw collars or a removable saw sleeve.

- Our Model 524-DC/SR Series with up to four moving saws. Selective ripping has never been more affordable. And now a NEW two arbor version of the Model 524 is available, arranged to edge lumber on first arbor and precision rip on the second arbor.

- Our Model 524-DC/SR 2 Plus Series for the ultimate production flexibility featuring a first arbor equipped with two shifting hogging blades to virtually eliminate edge strips and a second arbor with up to four shifting blades or 24" capacity fixed gang.

|

Inboard shifting saws allow quick access of fixed saw blades providing the industrys fastest change-overs. |

|

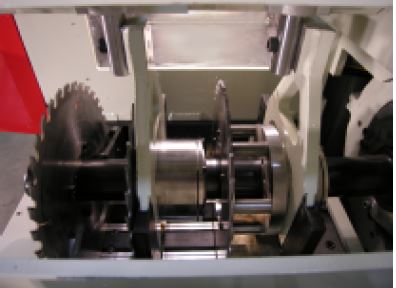

Heavy-duty overbeam with linear rails provides an extremely rigid support for the shifting saw carriages. |

|

Shifting hubs with wide land for stability provide 1” net rip minimums between shifting blades. |

|

Machine mounted laser stand with tip-back feature and open pressure head design facilitates alignment of laser reference lights with fixed saw blades. |

|

Severe-duty, high efficiency, cast iron, direct drive arbor motor provides reliable accuracy with no belts to tension or replace. |

|

UL / CSA approved electrical cabinet assembly. Other certifcation requirements available upon request. |

|

High friction Posi-Feed bed featuring aluminum slats with replaceable steel-backed rubber inserts. Precision feed chains ride on hardened steel Double-Vee rails. |

Capacity:

12” arbor space, thickness to 2-3/4” using 14” dia. tooling, 30” min. length for glue joint accuracy, 22” min. length bust-up only.

Shifting Saw(s):

One outboard shifting blade in combination with fixed saws. One inboard shifting blade in combination with fixed saws. Two inboard shifting blades in combination with fixed saws. 1” min. width net rip between shifting saws, 1-1/8” min. net rip between TwistLock saw mounted saw collars (when using individual hold down shoes).

Laser Lights:

Machine mounted laser light stand arranged for mounting up to six laser lights. One traveling laser light provided for each shifting saw and integrated with saw movement.

Arbor Drive:

Direct drive 50 HP, 3600 RPM TEFC Mereen-Johnson saw arbor motor.

Feed Drive:

3 HP with variable frequency speed control, infinately variable, 30’-235’ per minute.

Feed Bed:

Posi-Feed friction feed bed of structural aluminum feed slats with replaceable steel backed rubber inserts carried on precision Double-Vee hardened steel feed chains and track. Oil mist lubrication of feed system with low oil level auto feed shut-off.

Hold Downs:

Four 3” dia. air loaded press rolls. Air loaded traveling shoes provided for each shifting blade. Air loaded individual shoe or removable bed plate hold downs for fixed blades can handle up to 1/2“ thickness variation.

Anti-Kickbacks:

Single lower, double upper infeed. Single upper outfeed

Dust Collection:

One 10” dia. and one 5” dia. upper, one 5” dia. lower, 4,060 total CFM required.

Electrical:

Arranged for 3/60/230 or 460 volt power supply (other electrics available).

video1:

video2:

video 3:

Related Product

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map