Máy bào bốn mặt bản rộng - LMC PLANERMAC 450 mm

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

Máy bào bốn mặt bản rộng Leadermac - LMC PLANERMAC 450 mm

Thời gian bảo hành: Máy bào bốn mặt bản rộng - LMC PLANERMAC 450 mm

+ 12 tháng cho phần cơ

+ 06 tháng cho phần điện

- Vỏ bọc âm thanh và an toàn - Toàn bộ máy được bao phủ để giảm tiếng ồn và cải thiện độ an toàn

- Bàn ăn bằng crôm cứng - Bề mặt crôm cứng 0,3mm để tăng tuổi thọ sử dụng

- 3 Cài đặt áp suất giai đoạn của con lăn cấp liệu - Áp suất con lăn khí nén bù đắp cho sự chênh lệch lớn về độ dày phôi. Tối đa cài đặt áp suất không khí là 6 bar

- Bôi trơn dầu tự động cho bàn tiếp liệu - Tiếp dầu vào 2 điểm của bàn tiếp liệu với điều khiển hẹn giờ

- Bàn tiến dao 1,4 mét

- Phạm vi điều chỉnh cho bàn tiến dao và hàng rào ghép cạnh là 10mm.

- Hàng rào có chạm khắc không tham chiếu - Thân thép

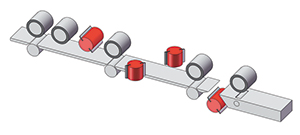

- Con lăn trên dẫn động bằng điện - Con lăn thép trước trục chính trên, con lăn cao su sau trục trên cùng theo tiêu chuẩn

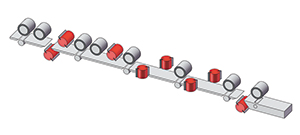

Bố trí trục chính & 5 con lăn dưới cùng được trang bị con lăn điều khiển điện trên bàn tiếp liệu.

Máy bào bốn mặt bản rộng - LMC PLANERMAC 450 mm

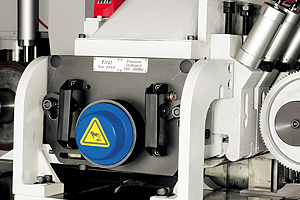

bảng điều khiển trung tâm

Chiều rộng và chiều sâu của thiết lập cắt có thể được thực hiện chính xác và thuận tiện thông qua bộ điều khiển kỹ thuật số trên bảng điều khiển.

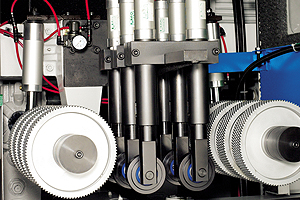

Con lăn cấp phôi khí nén

Các con lăn cấp liệu được nạp khí nén để có hiệu quả cấp liệu tuyệt vời. 3 giai đoạn, cài đặt áp suất con lăn cấp liệu.

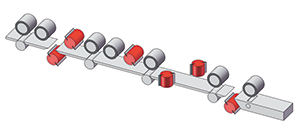

Bạc đạn đặc biệt cho đầu bào

Các đầu dao cắt ở dưới và trên đầu tiên được hỗ trợ bởi các vòng bi bổ sung bên ngoài, cung cấp một giá đỡ vững chắc.

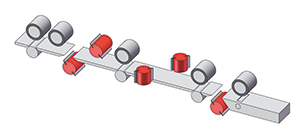

Con lăn đè được điều khiển khí nén

6 con lăn áp suất được điều khiển bằng khí nén được thiết kế đặc biệt được cung cấp trên trục chính dưới cùng đầu tiên đảm bảo độ êm ái tối đa cho việc cấp liệu và hoàn thiện bề mặt đáy hoàn hảo.

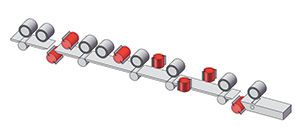

Bạc đạn tăng cường cho đầu bào

Đầu dao cắt phía dưới đầu tiên và trục chính cuối cùng được hỗ trợ bởi các vòng bi thủy lực bổ sung bên ngoài cung cấp một giá đỡ vững chắc. Giá đỡ ổ trục thủy lực mở rộng cũng cung cấp khả năng thay đổi đầu cắt thuận tiện bằng cách kéo nó ra.

Nếu phôi rộng hơn có thể đặt riêng

|

LMC-445 4-SPINDLE |

LMC-545 5-SPINDLE |

LMC-645 6-SPINDLE |

|

LMC-745 7-SPINDLE |

LMC-845 8-SPINDLE |

Xem Catalogue Máy bào bốn mặt bản rộng Leadermac - LMC PLANERMAC 450 mm

LEADERMAC Planermac series

Leadership Through Performance and Reliability

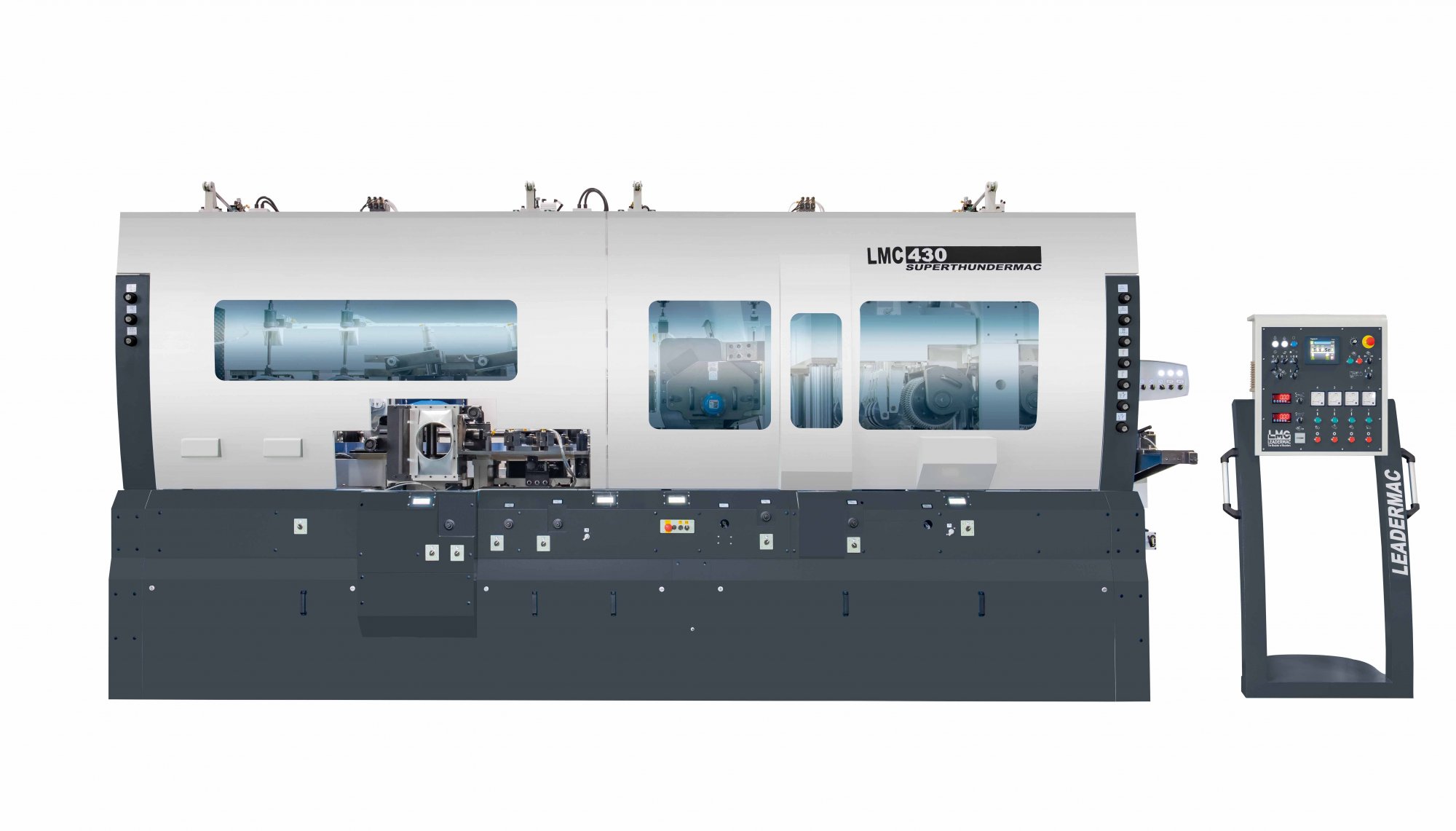

LEADERMAC's wide variety of 4 side moulders have all the very latest technologies for increased productivity. These heavy duty moulders are designed to provide fast cutting speed and high accuracy. The machines are precision manufactured by our highly skilled technicians - plus Leadermac service, training, and moulding know-how is offered. No matter what your moulding jobs call for, there is a Leadermac 4 side moulder that's right for you.

With fine features to give you the winning edge in 4 side moulding.

Ideal for producing profiled strips for construction material such as beams and boards etc... heavy & wider planning applications.

- Machine with optional chamfering unit

- Min. working width: 150mm

- Max. working width: 1300mm (with tool cutting circle of 163mm)

- Min. working thickness: 50mm

- Max. working thickness: 260mm (with tool cutting circle of 163mm)

- Minimum length of workpiece: 1500mm

- 1st bottom spindle – 40HP Allowable cutting circle 125 – 180mm

- 2nd top spindle – 40HP Allowable cutting circle 125 – 180mm

- 3rd right spindle – 30HP Allowable cutting circle 140 – 180mm

- 4th left spindle – 30HP Allowable cutting circle 140 – 180mm

- All spindles with inverter brake

- Up & down motor: 20HP x 1 inverter

- Spindle diameter: 70mm

- Spindle R.P.M: 5,500

- Feed speed, infinitely variable: 6 – 15m/min

Choice of machine models, from LMC-445 (4-spindle),

LMC-545 (5-spindle), LMC-645 (6-spindle),

LMC-745 (7-spindle) to LMC-845 (8-spindle).

World Class Moulding Solutions

- Sound and safety enclosure – The entire machine is covered to reduce noise and improve safety

- Hardened chrome feeding table – 0.3mm hardened chrome surface to increase service life

- 3 Stage pressure setting of feed roller – Pneumatic roller pressure compensates for large variances in workpiece thickness. Max. air pressure setting is 6 bar

- Automatic oil lubrication for feeding table – Supplies oil on the 2 points of feeding table with timer control

- 1.4 meter infeed table

– Adjustment range for infeed table and edge-jointing fence is 10mm.

– Infeed fence with non-reference engraving - Steel body

- Power driven upper roller – Steel rollers before top spindle, rubber rollers after top spindle under standard

spindle arrangement & 5 units of bottom roller are equipped with power driver roller on the feed table.

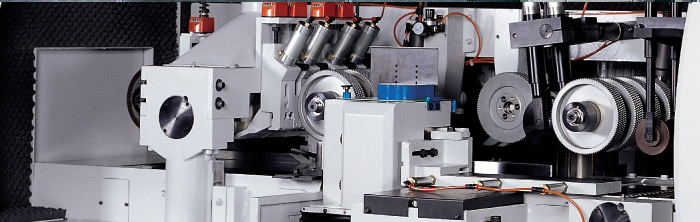

OUTBOARD BEARING SUPPORT ON HORIZONTAL SPINDLE

The horizontal spindle is equipped with outboard bearing support, providing solid support.

POWER DRIVEN UPPER ROLLERS

Steel rollers before the top spindle and rubber rollers after the top spindle are designed for standard spindle arrangement.

POWER DRIVE BOTTOM ROLLERS

5 units of bottom rollers on the feed table are powered, increasing the wood infeed effect.

FLOATING VERTICAL SPINDLE

This function is especially suitable for cutting bent wood. With this function, the vertical spindle can accurately cut along the wood curvature. Allowable maximum wood curvature is 50mm.

DOUBLE SIDE COLUMN SUPPORTING (OPT.)

Double side column supporting for top pressure feeding rollers

This function is especially suitable for working width over 500mm, these feed rollers provide steady feeding and even feeding with double side column supporting.

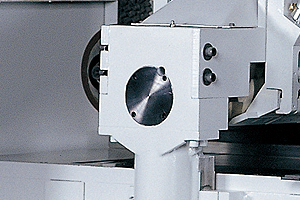

OVERSIZED OUTBOARD BEARING FOR CUTTERHEAD

The first bottom cutterhead and the final spindle are supported by additional hydro outboard bearings, providing solid support. The oversized hydraulic bearing supports also provide convenient cutterhead change by pulling it out.

PNEUMATIC CONTROL PRESSURE ROLLERS

Specially designed 6 pneumatically controlled pressure rollers provided on the first bottom spindle assure maximum smoothness for work feeding and perfect surface bottom finish.

SUPER PLANERMAC LMC-4130PL

CHAMFERING MECHANISM (OPT.)

The machine is equipped with 4 chamfering cutters at the outfeed end. After the wood is moulded, the chamfering mechanism cuts the 4 corners of the wood simultaneously.

QUICK CHANGE INSERTS

Changing inserts on a spiral cutterhead is quickly performed by simply pulling out the top or bottom horizontal cutterhead.

PNEUMATIC FEEDING ROLLERS

The feed rollers are pneumatically loaded for excellent feeding effect. 3 stage, feed roller pressure setting.

OUTBOARD BEARING FOR CUTTERHEAD (STD.)

The first bottom and top cutterheads are supported by additional outboard bearings, providing a solid support.

Extra Large CapacityRuggedly Built

When jobs call for heavy duty 4-side moulding for extra large wood, the Planermac series from Leadermac, with working widths ranging from 450mm to 1300mm, is the perfect solution.

OUTSTANDING FEATURES:

- Programmable controller provides convenient width and depth of cut setting.

- The full safety enclosure serves as a chip guard and helps to reduce noise.

- Pneumatic pressure of the feed rollers can be easily set to provide an outstanding feeding effect.

- Table surface is hard-chrome plated for maximum wear resistance.

- Steel body machine frame is specially heat treated for maximum stability and rigidity.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- The smooth initial feeding of stock is achieved by means of independently pneumatic feed rollers.

Quality come from Excellent equipment of production.

CENTRALIZED GREASING UNIT

The centralized greasing unit delivers grease to all slides to ensure smooth movement.

OVERSIZED OUTBOARD BEARING FOR CUTTERHEAD

The first bottom cutterhead and the final spindle are supported by additional hydro outboard bearings, providing solid support. The oversized hydraulic bearing supports also provide convenient cutterhead change by pulling it out.

PROSET CONTROLLER (OPT.)

- 19" panel PC

- Product library (1000 sets)

- Knife library (10,000 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Workpiece settings on any axis as desired

- The width and thickness settings can be easily set using the programmable controller

- All axes are equipped with ballscrews and rotary encoders for feedback position control, providing high positioning accuracy and better cutting quality

- The desired values for width and thickness can be conveniently pre-set and are displayed on an LED readout

CONTROLLER

The speed is VFD Inverter controlled, and all electrical components meet CE, UL & CSA standards.

EASYSET CONTROLLER (OPT.) Touch Screen Control

- 5.7" HMI (Memory 200 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Workpiece settings on left and top axes as desired

- The width and thickness setting can be easily set using the programmable controller

- The desired values for thickness are displayed on and LED readout

SMARTSET CONTROLLER(OPT.) Touch Screen Control.

- 9" HMI (Memory 300 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Setworks on any axis as desired

- The Motorized Axes: derived by inverter, transmitted by ball screw, feedback by encoder

- The desired values for radial and axial are displayed on HMI.

Danh mục : máy bào, máy bào - chuốt chốt

>Máy bào bốn mặt bản rộng Leadermac - LMC PLANERMAC

LMC 245PL to LMC11106PL

| STANDARD EQUIPMENT / Planermc - LMC 245PL to LMC11106PL | Standard Base Equipment | Available Options |

| Number of Spindles, min-max | 2 to 11 | Special Machine Configurations on request |

| Working Width (at a tool cutting circle of 125mm-200mm) | 15~450mm (0.59"~17.7") | 500mm (20") ; 600mm (24") ; 700mm (27.5") ; 1300mm (51.1") |

| Working Thickness (at a tool cutting circle of 125mm-200mm) | 10~200mm (0.39"~7.1") | to 200mm (8") ; to 250mm (10") ; to 300mm (12") ;or to 350mm (14") |

| Basic Spindle Motor capacity (Wye Delta Soft Starts on All Motors) | 11 KW / 15HP | to 75KW (100HP) |

| Spindle Speed | 5500 RPM | 6000 RPM or 7200 RPM |

| Spindle Diameter | 50mm (2") | 1 13/16" or 2 1/8" |

| Tool Cutting Circle,1st Bottom Spindle, min-max | 125~180mm (5"~7.1") | |

| Tool Cutting Circle, Vertical Spindles, Left, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Tool Cutting Circle, Vertical Spindles, Right, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Tool Cutting Circle, Horizontal Spindles, Top, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Tool cutting circle, Horizontal Spindles, Bottom, min-max | 125~200mm (5"~8") | to 250mm (10") |

| Feed Motor | 3.7 KW / 5HP / INVERTER | to 15kw (25 HP) |

| Feed Speed, infinitely variable by VFD Inverter duty Motor | 6~24 m/min (20~80FPM) | to 36mpm (120fpm) ; 48mpm (160fpm) ; 60mpm (200fpm) or 90mpm (300fpm) |

| Top Feed Roller Diameter | 200mm (8") | |

| Top Feed Roller Width | 4 x 50mm (2") | |

| Pneumatic Pressure for feed rollers, max | 6 bar (85psi) | |

| Adjustment range for infeed table and edge-jointing fence | 10mm (0.4") | |

| Adjustment range for vertical spindle (axial) | 40mm (1.57") | |

| Adjustment range for horizontal spindle (axial) | 20mm (0.78") | |

| Length of the Infeed Straightening Table | 1.4M (55") | 1M (39") ; 2M (78") ; 2.5M (98") or 3M (120") |

| Mechanical digital readouts for the pressure shoes & hold-down unit | Included | |

| Full Sound and Safety Enclosure w/ Strobe-free Lighting | Included | Extra Insulation with Steel Punched Sheet Steel Ineterior |

| Motorized vertical adjustment of Feed Beam | Included | |

| Pneumatic Lateral Pressure Roller System opposite first right spindle | Included | |

| Extra HD Chainless Cardan Shaft Feed System w/ExHD Gearboxes | Included | |

| Quick Set Setworks on Near Side Head (s) & Top Heads (Radial Set) | Included | optional on all Axis and SmartSet Controls as noted Below optional |

| OPTIONAL EQUIPMENT : | |

| To CE Standards | Setting and Measuring Devices for the grinding room |

| Chanfering Heads for Material Corners | SINGLE Digital Readout and Quick Set to Main guide & Infeed Rolls-table |

| Straight &/or Profile Jointers any heads | (1, 1.4 & 2M Table) |

| Tilting Side Heads | Additional Quick Set Setworks on any desired Cutterhead Axis |

| Split Pressure Shoes | Outboard Top Feed roll Bearing Supports (optional on 450mm machine - Std. on all other |

| Directly Opposed Side Heads | machines |

| Rip Saw Section with up to 75kw (100HP) | Electronic Rotary Encoder Digital Readouts in lieu of mechancial counters - not required |

| Left (Opposite) Hand Feed | with SmartSet Controls as included |

| Inverter Motor Cutterhead Brakes | Hydro-Loc Outboards for Side Head Shafts that are 300mm(12") or 350mm(14") long |

| Cutterhead Lift Off Crane | |

Bài viết liên quan

- 1/ Đặc điểm nổi bật làm nên giá trị của máy bào 4 mặt Leadermac

- 2/ Top 3 thương hiệu máy bào bốn mặt siêu tốc độ bán chạy nhất hiện nay

- 3/ 4 loại máy bào gỗ tốc độ cao được nhiều xưởng nội thất chọn mua nhất

- 4/ Lợi ích nổi trội máy bào 4 mặt 6 trục dao so với dòng 4 và 5 dao

- 5/ 3 yếu tố quan trọng tác động tới giá máy bào 4 mặt

- 6/ Ưu điểm làm nên giá trị thương hiệu cho máy bào 4 mặt Leadermac

- 7/ Giải đáp thắc mắc máy bào 4 mặt Leadermac có tốt không

- 8/ Đơn vị cung cấp máy bào 4 mặt Leadermac tphcm giá gốc

- 9/ Giá trị cốt lõi chỉ có trong thương hiệu Leadermac

- 10/ Review ưu nhược điểm của máy bào 4 mặt Leadermac

Sản phẩm cùng loại

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

- Xem bản đồ

- 42/17, DT743, KP Bình Phước, P. Bình Chuẩn, Tp.Thuận An, Tỉnh Bình Dương.

- (84 274)3712 771

- 02743712768

- binhduong@vetta.com.vn

- Xem bản đồ