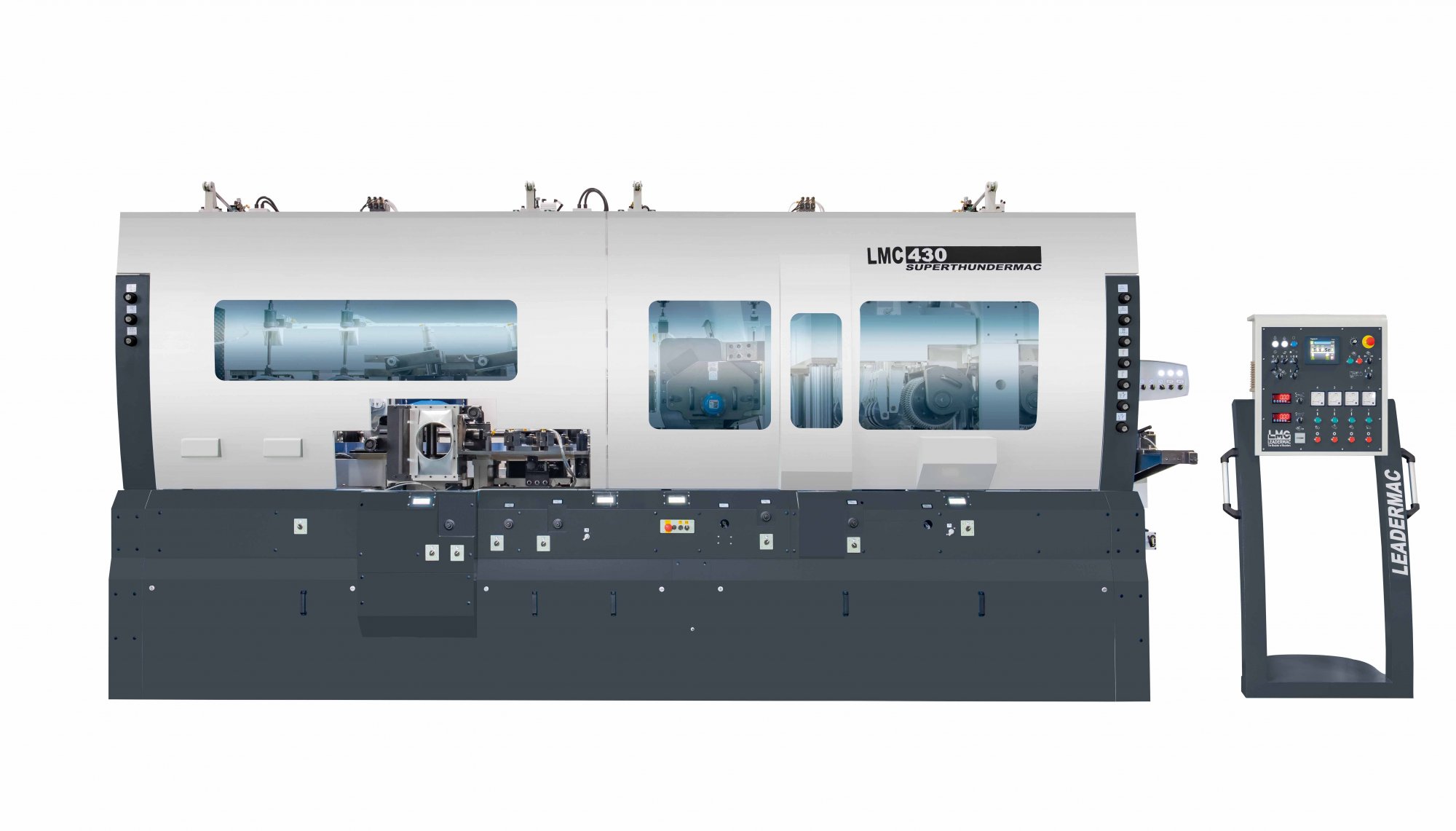

Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC

Thời gian bảo hành: Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC

+ 12 tháng cho phần cơ

+ 06 tháng cho phần điện

- Tất cả các moulders được trao chứng nhận CE.

- Tốc độ nạp liệu nhanh hơn lên đến 80 mét một phút (265 fpm) là tiêu chuẩn - đến 150 mpm (500fpm) - optional.

- Bộ điều khiển có thể lập trình cung cấp độ dày và chiều rộng của các thiết lập cắt thuận tiện.

- Có thể dễ dàng điều chỉnh từng trục chính bằng cách sử dụng mức điều chỉnh phía trước.

- Điều chỉnh độc quyền, riêng biệt của các trục quay dọc và các bàn đỡ cho phép các bàn này được đặt ở vị trí cực kỳ gần với các đầu dao cắt để tăng độ ổn định khi cắt.

- Vỏ an toàn đầy đủ đóng vai trò bảo vệ chip và giúp giảm tiếng ồn.

- Mỗi trục chính được điều khiển bởi một động cơ riêng để đúc mạnh mẽ và điều khiển dễ dàng.

- Có thể dễ dàng cài đặt nhiều áp suất khí nén của các cuộn cấp liệu để mang lại hiệu quả cấp liệu vượt trội.

- Mặt bàn được mạ crom cứng chống mài mòn tối đa.

- Tất cả các bộ phận quay và điều chỉnh bằng tay đều được đặt trong các ổ trục được bôi trơn bằng mỡ khô để bôi trơn không cần dầu.

- Bộ bôi trơn tự động được cung cấp để cung cấp dầu cho các bàn cấp liệu.

- Khung máy nguyên khối, Extra Heavy được xử lý nhiệt đặc biệt để có độ ổn định và độ cứng tối đa theo cấu hình tiêu chuẩn.

- Các con lăn cấp nguồn cung cấp nguồn cung cấp phôi ổn định và trơn tru ngay cả đối với các vật liệu đặc biệt mỏng hoặc mịn. Các con lăn vẫn hoàn toàn song song ngay cả sau khi sử dụng lâu dài.

- Các chỉ số kỹ thuật số cơ học cho tất cả các phần tử áp suất và đầu và các phần tử áp suất của trục chính trên cùng.

- Phần lắp ráp máy cắt phoi ở phía trước trục chính trên cùng.

- Điều chỉnh theo chiều dọc có cơ giới của trục chính bao gồm các đầu đọc kỹ thuật số của PC.

- Trục và vỏ bằng thép hợp kim tốt nhất với 2 bộ Vòng bi kép siêu chính xác trong mỗi trục. Tất cả đều được bôi trơn bằng mỡ vĩnh viễn.

- Được xây dựng trong các khớp nối thẳng và định hình cung cấp hoạt động chính xác với chất lượng hoàn thiện cao.

Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC

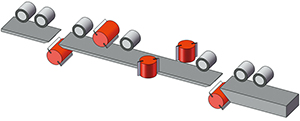

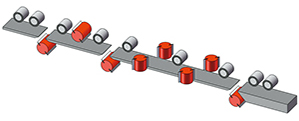

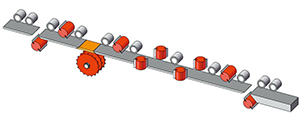

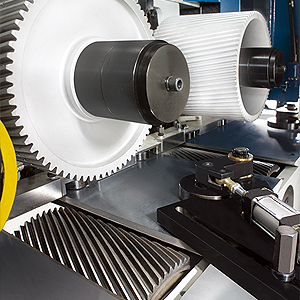

Con lăn cấp phối

Việc nạp liệu ban đầu trơn tru có được nhờ các cuộn nạp liệu trên và dưới được cấp nguồn độc lập.

Con lăn cấp phối đầu tiên được tự hành

Con lăn nạp liệu đầu tiên (có ly hợp tích hợp) được cấp nguồn, nhưng với tốc độ tiến dao cao, con lăn sẽ chạy tự do, loại bỏ hư hỏng có thể xảy ra đối với phôi và máy. Điều này cho phép vận hành trơn tru với tốc độ nạp đặc biệt cao.

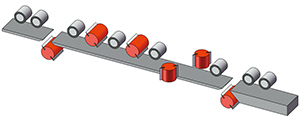

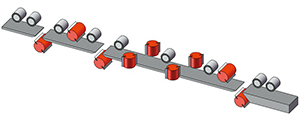

Thiết kế vận hành ổn định

Mặt khí nén mạnh mẽ, chịu tải nặng và giày áp lực cho trục chính bên trái cung cấp áp suất cực kỳ ổn định cho các hoạt động tốc độ cao. Một con lăn áp suất khí nén phía trước trục chính thẳng đứng bên phải đảm bảo nguồn cấp dữ liệu liên tục.

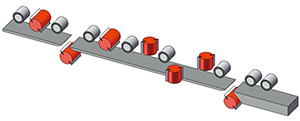

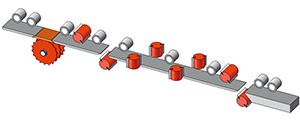

Điều chỉnh trục dễ dàng

Dễ dàng điều chỉnh tất cả các trục xoay từ phía trước. Tất cả các điểm điều chỉnh đều ở cùng độ cao, để điều chỉnh thuận tiện hơn và nhanh hơn.

Bộ đè độc lập hạng nặng

Miếng đệm áp suất chắc chắn và mạnh mẽ nằm phía trên trục chính dưới cùng và được gắn vào thân máy. Thiết kế này giúp giảm độ rung và tăng độ ổn định khi vận hành. Độ cao của miếng đệm được điều khiển bằng điện tử.

Bộ kẹp thủy lực tải nặng

Bôi trơn tập trung

Việc bôi trơn cho tất cả các bộ phận quan trọng được thực hiện thuận tiện nhờ sự bố trí tập trung các điểm bôi trơn.

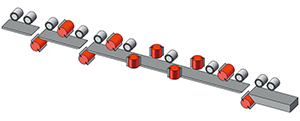

Hệ thống cấp phôi

Các con lăn tiến dao hoạt động cùng với một công tắc hành trình (cổng) để dừng máy nếu phôi quá dày hoặc bị gấp đôi.

Nếu phôi rộng hơn có thể đặt riêng

|

LMC-530 5-SPINDLE |

LMC-630 6-SPINDLE |

LMC-730 7-SPINDLE |

LMC-830 8-SPINDLE |

|

LMC-930 9-SPINDLE |

LMC-930 9-SPINDLE |

LMC-1030 10-SPINDLE |

LMC-1030 10-SPINDLE |

Xem Catalogue Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC

Super Thundermac 4-Spindle 4-Side Moulder

LEADERMAC Super Thundermac The Leading Edge in 4-side Moulding

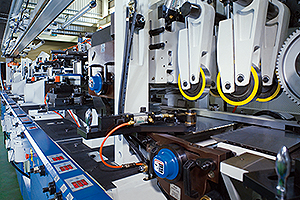

The concept behind Leadermac is to design and manufacture the most productive, most fine finish and extremely high accuracy moulders to create a competitive edge for our customers. With years of research and development, the new Super Thundermac series has been successfully developed to offer production speed beyond your expectations. With the Leadermac Super Thundermac, you can reduce your production costs, greatly shorten your delivery time and create more profits.

Gives You the Competitive Edge in Productivity and Accuracy

Built for super-high production requirements, the Super Thundermac series of 4-side moulder can bring your production speed to a new level.

The LEADERMAC Super Thundermac series features 200m/min. feed speed as standard. Higher feed speeds of 300m/min. are also available. This, combined with a 6000 RPM spindle speed, makes the moulder exceptionally ideal for high speed cutting operations. The entire machine is ruggedly and compactly constructed for extra high stability during high speed operation. In addition, the Super Thundermac is equipped with a user-friendly PLC control combined with touch-sensing for maximum operational convenience.

For All Your woodworking Applications

- Choice of Machine Models - from Super Thundermac

- LMC-430ST (4-spindle) to LMC-1030ST (10-spindle).

OUTSTANDING FEATURES:

- All moulders awarded with CE certification.

- Faster feed speeds of up to 200 meters a minute (656 fpm) are standard - to 300 mpm (984 fpm) - optional.

- Adjustment of each spindle can be easily performed using the front adjustment level.

- Exclusive, separate adjustment of the vertical spindles and the support tables allows the tables to be positioned extremely close to the cutterheads for added cutting stability.

- Each spindle is driven by an individual motor for powerful moulding and easy control.

- Multiple pneumatic pressure of the feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces are hard-chrome plated for maximum wear resistance.

- All manually adjusted and turning parts are housed in dry grease lubricated bearings for oil-free lubrication.

- Automatic lubricator is provided to supply oil to the feed tables.

- Extra Heavy machine frame is specially heat treated for maximum stability and rigidity by standard configuration.

- The powered outfeed rollers provide stable and smooth workpiece outfeed even for especially thin or smooth materials. The rollers remain perfectly parallel even after long-term use.

- Mechanical digital readouts for the pressure elements of top spindle.

- Sectional Chip Breaker Assembly in front of top spindle.

- Finest Alloy Steel Spindles and housings with 2 sets of Ultra Precision Duplex Bearings in each spindle. All are permanently grease lubricated.

- Built in Straight and Profile jointers provide accurate operation with high quality finish (Opt.)

PNEUMATICALLY ACTUATED FRONT DOOR

The front door of the machine is pneumatically controlled and is easy to open, making it convenient for the operator to inspect the machine and conduct maintenance.

CROSS BEAM

The cross beam consists of two areas. The infeed area is supported by 4 posts to ensure stability.

Speed Up Your Moulding Operations with the Latest Technological Breakthroughs from LEADERMAC.

POWERED INFEED ROLLER

The smooth initial feeding of the stock is achieved by means of the independently powered top and bottom infeed rolls.

SELF ACTUATING FIRST FEED ROLLER

The first feed roller (with built-in clutch) is powered, but with high speed infeed, the roller will run freely, eliminating potential damage to the workpiece and machine. This allows for smooth operation with exceptionally high feed speeds.

DESIGNED FOR PARAMOUNT STABILITY

Powerful, heavy-duty pneumatic side and pressure shoes for the left spindle provide extremely stable pressure for high-speed operations. A pneumatic top pressure roller in front of the right vertical spindle ensures constant stock feed.

Delivering Unparalleled Speed and Power in a High-Efficiency Automated System

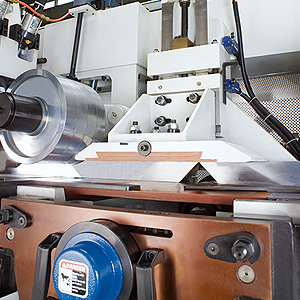

INFEED FENCE COOLING (OPT.)

The infeed fence is cooled by a water cooler, which can effectively avoid thermal growth and deformation on the infeed fence during high speed machining.

AIR SPRING LOADED PRESSURE WHEEL

The side pressure wheel at the infeed end of the machine is loaded by air spring for consistent holding pressure, which ensures stable and smooth infeed of wood.

State-of-the-Art Control

Perfectly Designed to Optimize Moulding Efficiency

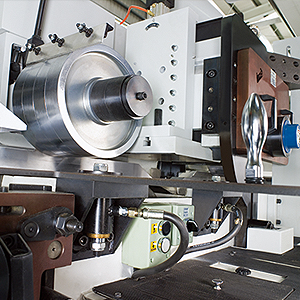

RIGID, PRECISION SPINDLE 6,000 RPM STANDARD

The spindle is precision machined from high quality steel, specially heat treated, precision ground and dynamically balanced, assuring extremely smooth running, high cutting accuracy and high stability. Each spindle is water-proof and dust-proof to ensure long service life.

CENTRALIZED LUBRICATION POINTS

Greasing to all critical parts is conveniently made by the centralized arrangement of lubrication points.

DUST WIPER

Top and bottom feed rollers are equipped with dust wipers to remove dust from the feed rollers.

PRESSURE PLATE COATED WITH TUNGSTEN CARBIDE

The front pressure plates for the top horizontal spindles and the right/left vertical spindles are coated with tungsten carbide for maximum wear resistance.

The Power and Precision for World-class Production Quality

Quality Proven by Worldwide Customers. Designed with High Production in Mind

The LEADERMAC 4-side molder is a compact power package that integrates high speed and heavy cutting operations, high accuracy, plus minimum trouble to maximize its impressive cutting capabilities. To ensure outstanding cutting results, the 6,000 rpm high speed spindle is carefully manufactured and tested before assembling. High feed speed up to 200 M/min. is driven by a frequency inverted motor, providing variable speed change. Our objective is to enhance each 4-side molder from LEADERMAC in order to upgrade your throughput and create more profits.

POWERED TOP AND BOTTOM FEED ROLLERS

Convenient spindle adjustment

Top and bottom feed rollers are powered for powerful and smooth feeding effect.

SIDE PRESSURE PLATE CLAMPED HYDRAULICALLY

The side pressure plate is clamped securely by hydraulic power.

BALLSCREW AND LINEAR GUIDEWAY

Adjustment for all spindles is transmitted through ballscrews in combination with movement on linear guideways for smooth movement and accurate positioning.

Digital readouts are provided for accurate reading of adjustment amount.

PROSET CONTROLLER (OPT.)

- 19" panel PC

- Product library (1000 sets)

- Knife library (10,000 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Workpiece settings on any axis as desired

- The width and thickness settings can be easily set using the programmable controller

- All axes are equipped with ballscrews and rotary encoders for feedback position control, providing high positioning accuracy and better cutting quality

- The desired values for width and thickness can be conveniently pre-set and are displayed on HMI

CONTROLLER

The speed is VFD Inverter controlled, and all electrical components meet CE, UL & CSA standards.

EASYSET CONTROLLER (OPT.) Touch Screen Control

- 5.7" HMI (Memory 200 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Workpiece settings on left and top axes as desired

- The width and thickness setting can be easily set using the programmable controller

- The desired values for thickness are displayed on and LED readout

SMARTSET CONTROLLER(OPT.) Touch Screen Control.

- 9" HMI (Memory 500 sets)

- Automatic machine quick setup

- Easy and powerful functionality

- Setworks on any axis as desired

- The Motorized Axes: derived by inverter, transmitted by ball screw, feedback by encoder

- The desired values for radial and axial are displayed on HMI.

Danh mục : máy bào, máy bào - chuốt chốt

Máy bào bốn mặt siêu tốc độ - SUPER THUNDERMAC LMC 523, 623, 723, 823, 923, 1023

| STANDARD EQUIPMENT: | Standard Base Equipment | Available Options |

| Working width | 30-300mm(1.18"-11.8") | |

| Working Thickness | 10-150mm(0.4"-5.9") | |

| Number of spindles, min-max | 4 to 10 | |

| Motor capacity per spindle | 37kw / 50HP | 45 kw / 60 HP |

| Spindle speed | 6,000 RPM | |

| Spindle diameter 60mm - std. | 60mm (2 3/8") | |

| Head cutting circle, 1st bottom spindle, min-max | 160-260 mm (6.3"-10.24") | 200-300 mm (7.87"-11.8") |

| Head cutting circle, vertical spindles, left, min-max | 160-260 mm (6.3"-10.24") | 200-300 mm (7.87"-11.8") |

| Head cutting circle, vertical spindles, right, min-max | 160-260 mm (6.3"-10.24") | 200-300 mm (7.87"-11.8") |

| Head cutting circle, horizontal spindles, top, min-max | 160-260 mm (6.3"-10.24") | 200-300 mm (7.87"-11.8") |

| Head cutting circle, horizontal spindles, 2nd/3rd bottom, min-max | 160-260 mm (6.3"-10.24") | 200-300 mm (7.87"-11.8") |

| Standard Feed motor | 56 kw / 75 HP | 75 kw / 100 HP |

| Feed speed, infinitely variable by frequency driven motor | 30-200 m/min (98-656 fpm) | 30-300 m/min |

| Feed roller diameter | 300 mm (11.8") | |

| Feed roller width | 4 x 50 mm (2 x 1.97") | |

| Pneumatic pressure for feed rollers, max | 6 bar | |

| Adjustment range for infeed table and edge-jointing fence | 10mm (0.4") | |

| Adjustment range of vertical spindles (axial) | 100 mm (3.94") | |

| Adjustment range of horizontal spindles (axial) | 40mm (1.58") | |

| Length of the straightening (moulder infeed) table | 1.57 M | |

| Diameter of dust hood for vertical spindle | Ø200 mm (7.87") | |

| Diameter of dust hood for horizontal spindle (top / bottom) | Ø250 mm (9.84") / Ø200 mm (7.87") |

| OPTIONAL EQUIPMENT: | |

| Fence & table with cooling system | Straight jointer(s) |

| Maximum working thickness 180 mm (7.1") | Profile jointer(s) |

| Increased motor horsepower available |

Bài viết liên quan

- 1/ Đặc điểm nổi bật làm nên giá trị của máy bào 4 mặt Leadermac

- 2/ Top 3 thương hiệu máy bào bốn mặt siêu tốc độ bán chạy nhất hiện nay

- 3/ 4 loại máy bào gỗ tốc độ cao được nhiều xưởng nội thất chọn mua nhất

- 4/ Lợi ích nổi trội máy bào 4 mặt 6 trục dao so với dòng 4 và 5 dao

- 5/ 3 yếu tố quan trọng tác động tới giá máy bào 4 mặt

- 6/ Ưu điểm làm nên giá trị thương hiệu cho máy bào 4 mặt Leadermac

- 7/ Giải đáp thắc mắc máy bào 4 mặt Leadermac có tốt không

- 8/ Đơn vị cung cấp máy bào 4 mặt Leadermac tphcm giá gốc

- 9/ Giá trị cốt lõi chỉ có trong thương hiệu Leadermac

- 10/ Review ưu nhược điểm của máy bào 4 mặt Leadermac

Sản phẩm cùng loại

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

- Xem bản đồ

- 42/17, DT743, KP Bình Phước, P. Bình Chuẩn, Tp.Thuận An, Tỉnh Bình Dương.

- (84 274)3712 771

- 02743712768

- binhduong@vetta.com.vn

- Xem bản đồ