Máy bào gỗ bốn mặt - LMC SMARTMAC Frame

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

Máy bào gỗ bốn mặt - LMC SMARTMAC Frame

Thời gian bảo hành: Máy bào gỗ bốn mặt - LMC SMARTMAC Frame

+ 12 tháng cho phần cơ

+ 06 tháng cho phần điện

- Tất cả các moulders đều được cấp chứng nhận CE.

- Khung máy bằng gang đúc 1 mảnh được xử lý nhiệt đặc biệt để có độ ổn định và độ cứng tối đa như cấu hình tiêu chuẩn.

- Tốc độ nguồn cấp dữ liệu nhanh hơn là tiêu chuẩn lên tới 24 mét một phút (80 fpm).

- Việc điều chỉnh từng trục chính ngoại trừ trục chính cuối cùng có thể dễ dàng thực hiện bằng cách sử dụng cần điều chỉnh phía trước.

- Mỗi trục chính được điều khiển bởi một động cơ riêng để khoan mạnh mẽ và điều khiển dễ dàng.

- Có thể dễ dàng đặt áp suất khí nén của các cuộn nạp liệu trên cùng để mang lại hiệu quả nạp liệu vượt trội.

- Mặt bàn được mạ crom cứng để chống mài mòn tối đa.

- Tất cả các bộ phận quay được điều chỉnh bằng tay đều được đặt trong các ổ trục được bôi trơn bằng mỡ vĩnh viễn để bôi trơn không cần dầu.

- Vỏ an toàn đầy đủ đóng vai trò như một tấm bảo vệ chip và mảnh đồng thời giúp giảm tiếng ồn.

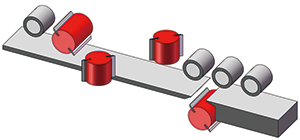

Có thể nâng hạ con lăn phụ

Cơ chế này cung cấp thêm độ trơn cho quá trình cấp phôi ngắn. Các con lăn cấp liệu phụ được truyền động bằng điện để nạp liệu dễ dàng và có thể nâng lên để thay đổi hoặc thiết lập dao cắt thuận tiện.

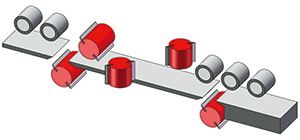

có bánh đè bên phía trên trục số 3

Mang lại hiệu ứng nguồn cấp dữ liệu tích cực cho nguồn cung cấp ngắn và hẹp.

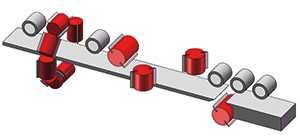

Universal Spindle (LMC-423S & LMC-523S)

Trục xoay đa năng có thể được vận hành theo chiều ngang, chiều dọc hoặc ở bất kỳ góc nào ở giữa. Độ cao ngang trục chính được cung cấp năng lượng giúp thiết lập nhanh chóng.

Standard Infeed Table Length - 2 meters (78").

Một loạt các cấu hình trục chính (các cấu hình khác có sẵn theo yêu cầu)

|

LMC-423 4-SPINDLE |

LMC-523 5-SPINDLE |

LMC-523S with universol spindle 5-SPINDLE |

Xem Catalogue Máy bào gỗ bốn mặt - LMC SMARTMAC Frame

Picture shown is LMC-423S - Standard Infeed Table Length - 2 meters (78").

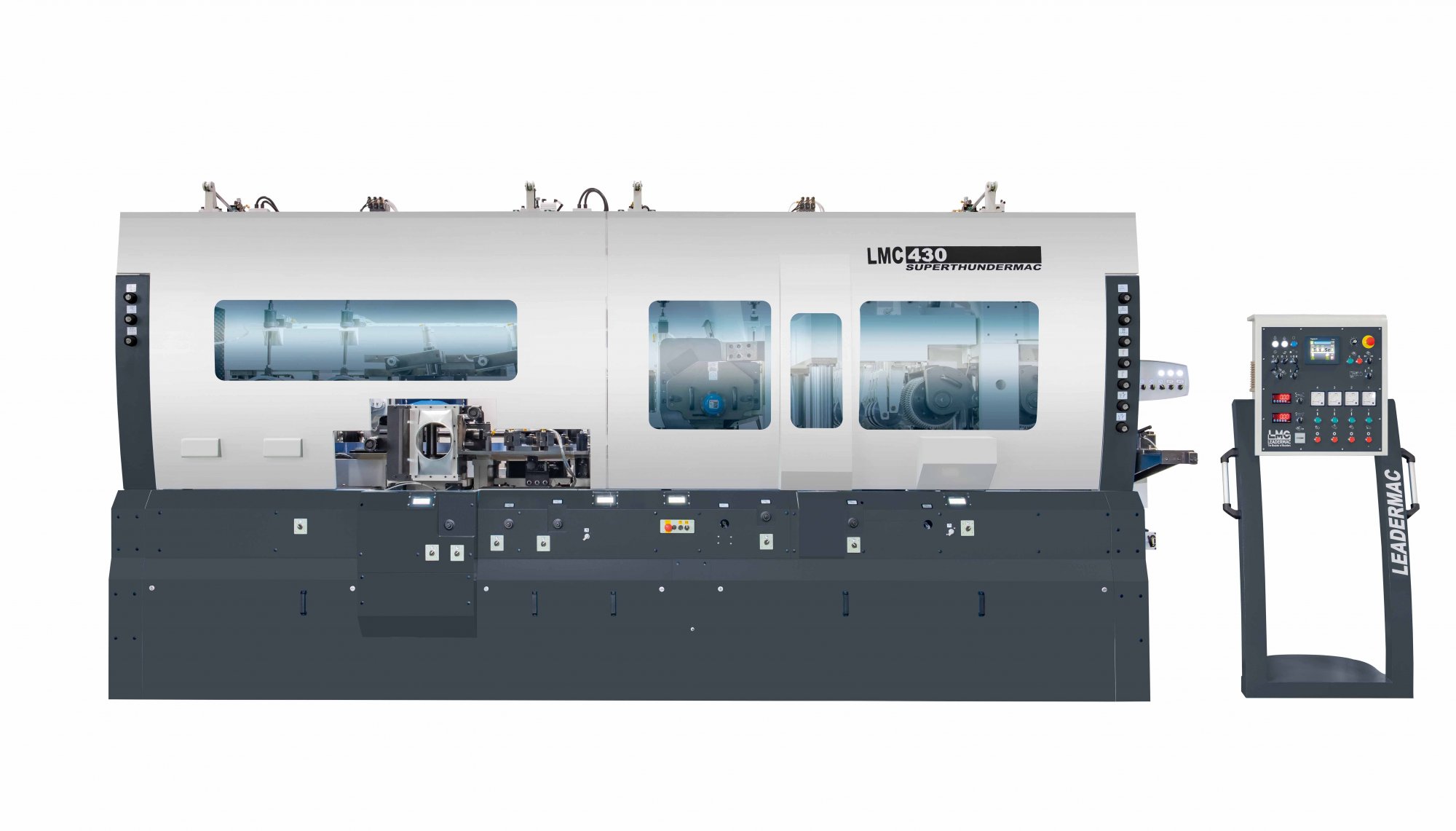

LEADERMAC Smartmac Series - The Leading Edge in 4-side Moulding

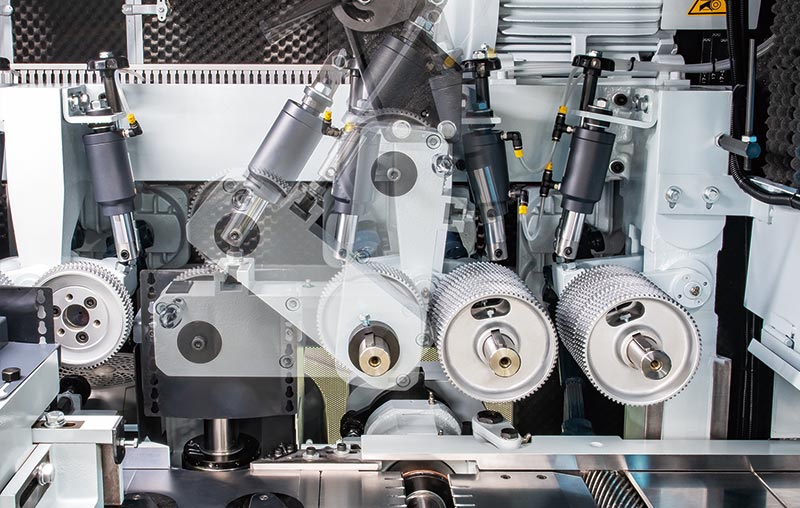

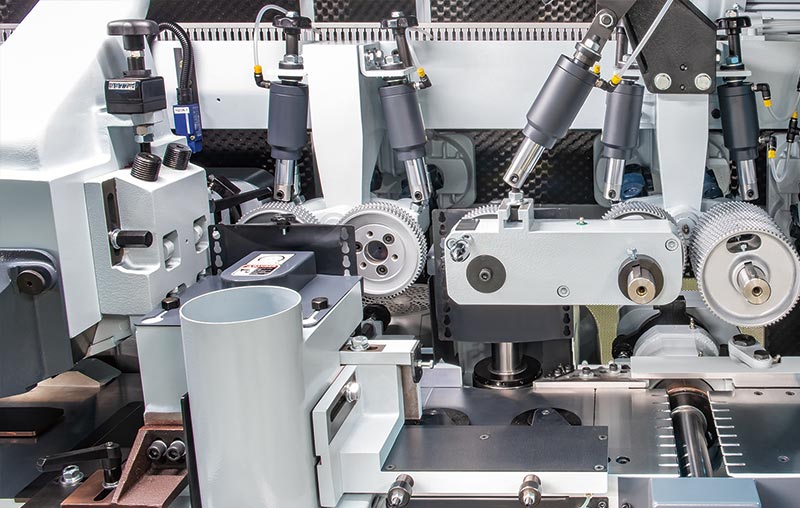

The LEADERMAC Smartmac Series 4-side moulder is designed to perform wood moulding more efficiently by optimizing the machine capacity. Its cast iron machine frame provides high rigidity and high stability for years of dependable deformation-free operation. The Smartmac series also features advanced design, making it unique in the industry.

Choice of Machine Models - from LMC-423S (4-Spindle) to LMC-523S (5-Spindle)

OUTSTANDING FEATURES:

- All moulders awarded CE certification.

- 1-piece, Cast Iron Machine Frame is specially heat treated for maximum stability and rigidity as standard configuration.

- Faster Feed Speeds of up to 24 meters a minute(80 fpm) are standard.

- Adjustment of each spindle except last bottom spindle can be easily performed by using the front adjustment levers.

- Each spindle is driven by an individual motor for powerful drilling and easy control.

- Pneumatic Pressure of the top feed rolls can be easily set to provide an outstanding feeding effect.

- Table surfaces are hard-chrome plated for maximum wear resistance.

- All manually adjusted turning parts are housed in permanent grease lubricated bearings for oil-free lubrication.

- The Full Safety Enclosure serves as a chip and piece guard and helps to reduce noise.

FEATURES:

The Ultimate 4-Side Moulder from LEADERMAC

Superior Performance! Increased Productivity!

ADJUSTABLE CUTTERHEAD GUARD

The cutterhead guard for the vertical spindle can be adjusted to suit various cutterhead sizes.

A graduated scale is provided to indicate the guard adjustment amount.

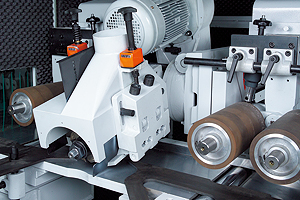

VERSATILE LAST SPINDLE

The last top horizontal spindle can be fitted with planing knives or multiple sawblades.

SIDE PRESSURE WHEELS FOR THIRD SPINDLE

Provides positive feed effect for short and narrow stock.

POWERED INFEED BOTTOM ROLLER

Powered Infeed Bottom Roller (actually More Powered Top & Bottom Feed Rolls than almost all of our competition.) The smooth initial feeding of the stock is achieved by means of the independently powered infeed rollers.

LIFTABLE AUXILIARY FEED ROLLER

The short stock powered feed mechanism provides added smoothness for short workpiece feeding. The auxiliary feed rollers are power driven for effortless feeding effect, and are quick-liftable for convenient cutterhead change or setup.

LED DISPLAY (OPTIONAL)

The desired values for thickness are displayed on the LED readout.

POWERED SPINDLE ADJUSTMENT (OPTIONAL)

The left vertical spindle can be power adjusted for quick set-ups.

FEED TABLE

The entire Cast Iron – Chromed Infeed table is normalization heat treated for maximum stability. Infeed Table adjustment is quickly accomplished by means of a quick-setting levers.

CONTROLLER

The speed is VFD Inverter controlled, and all electrical components meet CE, UL & CSA standards.

UNIVERSAL SPINDLE (OPTIONAL)

The universal spindle can be operated horizontally, vertically or at any angle in between. Powered universal spindle horizontal elevation provides quick set-ups.

EASYSET CONTROLLER (OPTIONAL) TOUCH SCREEN CONTROL

- 5.7” HMI (Memory 200 sets).

- Automatic machine quick setup.

- Easy and powerful functionality.

- Workpiece settings on left and top axes as desired.

- The width and thickness setting can be easily set using the programmable controller.

- The desired values for thickness are displayed on HMI..

Danh mục : máy bào, máy bào - chuốt chốt

Máy bào gỗ bốn mặt - LMC SMARTMAC Frame

| STANDARD EQUIPMENT: | Standard Base Equipment | Available Options |

| Working Width (at a tool cutting circle of 140 mm) Working Thickness (at a tool cutting circle of 163 mm) Number of Spindles, min-max |

15mm - 230mm (0.59" -9.1") 10-125mm (0.39"-4.9") 4 or 5 Spindles |

Universal - optional |

| Feed Motor | 5 HP / INVERTER | to 15 HP 7200 rpm 1 1/2", 1 13/16" |

| Feed Speeds, Infinitely Variable | 6-24 m/min (19.5-80 fpm) | |

| Base / Motor Power for 1st Bottom Spindle | to 7.5 KW / 10 HP-11 KW / 15 HP | |

| Base / Motor Power Per Spindle Except 1st Bottom Spindle | 7.5 KW / 10 HP | |

| Spindle Speed | 6000 RPM | |

| Spindle Diameter | 40mm (1.6") | |

| Tool Cutting Circle, First Bottom Spindle, Min-max | 125-160mm (4.9"-6.3") | |

| Tool Cutting Circle, Vertical Spindles, Left, Min-max | 112-180mm (4.4"-7.1") | |

| Tool Cutting Circle, Vertical Spindles, Right, Min-max | 112-180mm (4.4"-7.1") | |

| Tool Cutting Circle, Horizontal Spindles, Top, Min-max | 112-200mm (4.4"-8") | |

| Tool Cutting Circle, Horizontal Spindles, Bottom, Min-max | 112-200mm (4.4"-8") | |

| Feed Roll - Diameter | 140mm (5.5") | |

| Feed Roll - Width - Top Rolls | 50mm (2") each | |

| Feed Roll - Width - Bottom Roll (s) | Full Width | |

| Pneumatic / Air Pressure for feed rolls, max | 6 Bar (85psi) | |

| Adjustment Range for Infeed Table and Edge-Jointing Fence | 10mm (0.4") | |

| Adjustment Range of Vertical Spindles (Axial) | 20mm (0.8") | |

| Adjustment Range of Horizontal Spindles (Axial) | 20mm (0.8") | |

| Length of the straightening table | 2M (78.7") | 2.5M (98") & 3M (120") - optional |

| Diameter of Dust Hood for Vertical Spindle | Ø125mm (5") | |

| Diameter of Dust Hood for Horizontal Spindle | Ø125mm (5") | |

| Sectional Top Head Chipbreaker | Spring Tensioned - Std. | Pneumatic |

| Chainless HD Cardan Shaft Feed System | Std. | |

| Mechanical Digital Readouts for All Head Axis, Top Head Chip Breakers & Pressure Shoe | Std. | |

| Full Sound and Safety Enclosure with Srobless Lighting | Std. | |

| Motorized vertical adjustment of Feed Beam | Std. | |

| Lateral pressure Dual Rolls opposite first right spindle | Std. | Pneumatic |

Bài viết liên quan

- 1/ Đặc điểm nổi bật làm nên giá trị của máy bào 4 mặt Leadermac

- 2/ Top 3 thương hiệu máy bào bốn mặt siêu tốc độ bán chạy nhất hiện nay

- 3/ 4 loại máy bào gỗ tốc độ cao được nhiều xưởng nội thất chọn mua nhất

- 4/ Lợi ích nổi trội máy bào 4 mặt 6 trục dao so với dòng 4 và 5 dao

- 5/ 3 yếu tố quan trọng tác động tới giá máy bào 4 mặt

- 6/ Ưu điểm làm nên giá trị thương hiệu cho máy bào 4 mặt Leadermac

- 7/ Giải đáp thắc mắc máy bào 4 mặt Leadermac có tốt không

- 8/ Đơn vị cung cấp máy bào 4 mặt Leadermac tphcm giá gốc

- 9/ Giá trị cốt lõi chỉ có trong thương hiệu Leadermac

- 10/ Review ưu nhược điểm của máy bào 4 mặt Leadermac

Sản phẩm cùng loại

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

- Xem bản đồ

- 42/17, DT743, KP Bình Phước, P. Bình Chuẩn, Tp.Thuận An, Tỉnh Bình Dương.

- (84 274)3712 771

- 02743712768

- binhduong@vetta.com.vn

- Xem bản đồ