SCM Morbidelli CX200 CNC Drilling Center

SCM Morbidelli CX200 CNC Drilling Center

Warranty period: SCM Morbidelli CX200 CNC Drilling Center

+ 12 months for mechanical parts

+ 06 months for electrical parts

SCM MORBIDELLI CX200 CNC DRILLING CENTER

New technology to save investment costs

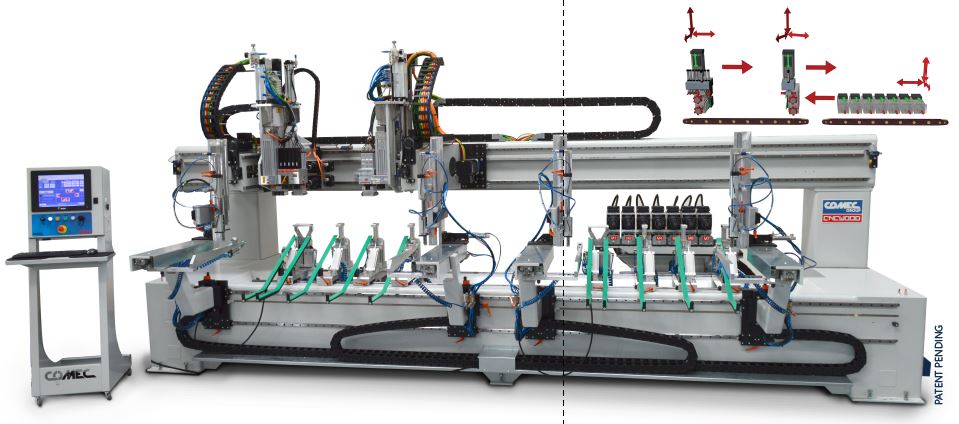

Ideal solution for mass production. The small and compact drilling center allows drilling on 5 faces of the board, cutting with a disc and milling thanks to two independent Y-axis heads that operate simultaneously on the same table.

Advanced Technology

Only within 10m2.

Precision Drilling

Thanks to the new RO.AX (Rotoaxial axis technology), the pair of clamping table has the best performance on the market and speed up to 8000 rpm.

High Productivity

Working cycle up to 600 units/hour, to go from one batch to another without the operator having to intervene to change the machine's equipment.

Morbidelli CX200

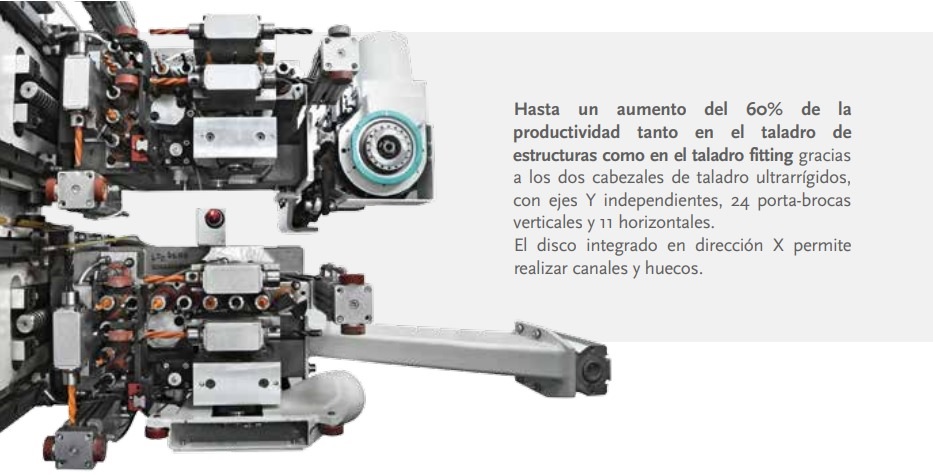

The Morbidelli CX200 is capable of drilling both structural and assembled joints, thanks to its two super-rigid drilling heads, independent Y-axis, 24 vertical drill spindle pairs, and 11 horizontal drill spindle pairs. An integrated X-direction disc allows for creating channels and holes.

The maintenance work is minimized with the use of RO.AX technology (Rotary Axis) drill chuck with over 1000 working hours.

The superior drilling quality is achieved by adjusting the rotational speed up to 8000 rpm and using a specialized press machine.

The high precision and speed of movement are controlled by brushless motors and slides on rack and pinion systems and ball screws on the X-Y axis and a ball screw with a recirculating nut on the Z-axis.

Performance and Reliability

The electric clamp spindle with 6.6 kW power and HSK63-F connection joint with a speed of up to 24,000 rpm is an ideal solution for local milling on different types of plates. It allows for blind and through milling, making it a top-end solution.

Flexibility

The machine is flexible with the ability to change between 6 tool positions to have all the necessary tools for any type of furniture job required.

Convenience

Thanks to the side supports, the operator can easily lift and load panels up to 3050 mm.

Related Product

- 175 Hoa Lan Str., Ward 2, Phu Nhuan Dist. Hochiminh City. Vn

- (+84) 8 3517 3407

- (+84) 8 3517 3407

- Vetta@vetta.com.vn

- View map

- 42/17 DT743, Binh Phuoc B, Binh Chuan, Thuan An,Binh Duong

- (84.650) 3712 771

- (84.650) 3712 768

- binhduong@vetta.com.vn

- View map