Máy chà nhám thùng trục tam giác Sheng Shing SHD series

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

Máy chà nhám thùng trục tam giác Sheng Shing SHD series

Feature

.Automatic memory modular design

.Electronic segmented pad control

.The individual component of pressure controlling system

.Automatic positioning and preset parameter

.Pressure can be applied in accordance with different edge

|

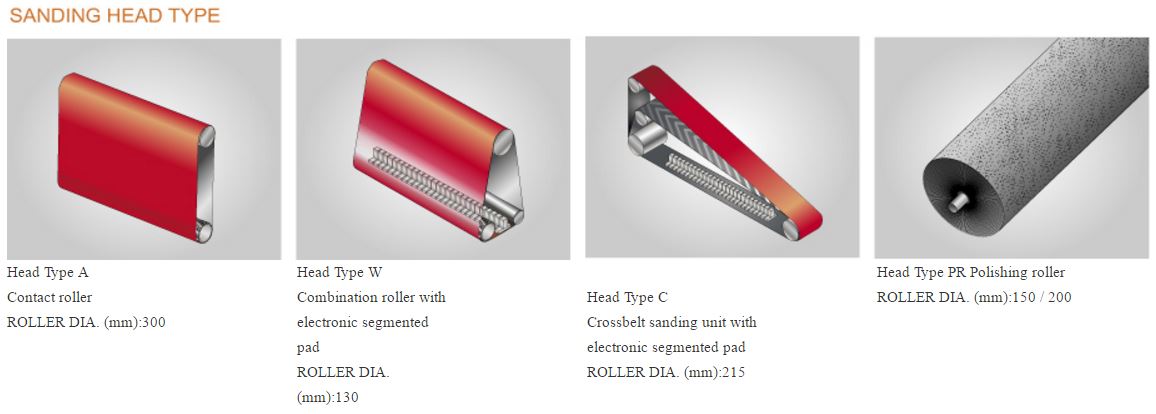

COLOR DIGITAL READOUT CONTROLLED .The machine equiped with industrial computer along with colorful touch screen. |

|

SENSOR SYSTEM Scanning by 20mm pitch to analysis of workpiece size and input to the computer for the pressure setting. Computer-controlled cylinder, thereby driving the pressure beam sanding. The cylinder is clean-free. |

|

AUTOMATIC STOP Limit switches are fitted at both sides of the sanding belt to prevent the belt running from the track. The machine will stop automatically if there is no air supply, INFEED EMERGENCY BRAKE Infeed emergency brake for operator stop the machine easily. EMERGENCY STOP BUTTON Below the PLC touch screen, there is an emergency stop button for operator press immediately. DISC BRAKE |

|

SANDING BELT OSCILLATION CONTROL .The sanding belt oscillation is controlled by a dust proof air eye. |

|

QUICK RELEASE LOCKING HANDLE By using turn to loose the handle and pad, replacing sanding belt easily. |

|

INVERTER The machine is built with a high performance frequency inverter which can be adjusted for any desired speed to accommodate a variety of paint and panel characteristics. |

|

CONVEYOR DRIVING SYSTEM Conveyor speed controlled by inverter, it will automatically compensated to the best feeding status. Thus, the computer can be processed more accurate. HIGH QUALITY CONVEYOR BELT The machine employs an Italian imported high quality conveyor belt, ensuring extremely smooth feeding, minimum wear, and break free performance under normal usage. CONVEYOR BELT POSITION WHEEL Coveyor belt tracking adjusted by position wheel. |

|

VACUUM SUCTION This will not only prevent the veneer or lacquer from being over-sanded or the panel from slipping, but also increases the dust extraction effect. |

|

BELT CLEANING DEVICE To ensure a clean and smooth grain surface on the abrasive belt, air is blown to thoroughly clean any dust.This greatly increases the belt's life. Once the conveyor starts, the device is also starts. A timer is equipped for controlling the sanding intervals. |

|

SEGMENTED PAD SANDER .Automatic memory modular design |

|

BRUSH ROLLER Clear away the dust on the working piece in the final step. POLISHING ROLLER This polishing roller not only clear away the |

| 103"Model/Rubber Roller Dia.150mm | SDH-2-1300 | SDH-3-1300 | SDH-4-1300 | SDH-5-1300 |

| Max. working width | 1300 mm | 1300 mm | 1300 mm | 1300 mm |

| Max. working height | 120 mm | 120 mm | 120 mm | 120 mm |

| Main spindle motor | 20HP, 20HP | 20HP, 20HP, 20HP | 20HP, 20HP, 20HP, 20HP | 20HP, 20HP, 20HP, 20HP, 20HP |

| Feed motor | 3 HP | 3 HP | 5 HP | 5 HP |

| Table lifting & lowering motor (digital controlled) | 1 HP | 1 HP | 1 HP | 1 HP |

| Brush Roller Motor | 1/2 HP | 1/2 HP | 1/2 HP | 1/2 HP |

| Feed speed (inverter controlled) | 0~18 M/min | 0~18 M/min | 0~18 M/min | 0~18 M/min |

| Size of sanding belt | 1346 x 2620 mm | 1346 x 2620 mm | 1346 x 2620 mm | 1346 x 2620 mm |

| Dust exhausted | 8000 M³/hr | 11200 M³/hr | 14400 M³/hr | 17600 M³/hr |

| Compressed air consumed | 0.35 M³/min | 0.50 M³/min | 0.5 M³/min | 0.50 M³/min |

| Packing size | (L) 2500 mm, (W) 2270 mm, (H) 2470 mm | (L) 3500 mm, (W) 2300 mm, (H) 2470 mm | (L) 4500 mm, (W) 2300 mm, (H) 2470 mm | (L) 5500 mm, (W) 3000 mm, (H) 2470 mm |

| Net weight | 5500 kgs | 8000 kgs | 10000 kgs | 14900 kgs |

| Gross weight | 5950 kgs | 8550 kgs | 10900 kgs | 16000 kgs |

Sản phẩm cùng loại

- 175 Hoa Lan, Phường 2, Quận Phú Nhuận, TP.HCM

- Hotline: 079 2356 799 - 0274 3712 771

- (84.28) 3517 3407

- vetta@vetta.com.vn - info@vetta.com.vn - sales@vetta.com.vn

- Xem bản đồ

- 42/17, DT743, KP Bình Phước, P. Bình Chuẩn, Tp.Thuận An, Tỉnh Bình Dương.

- (84 274)3712 771

- 02743712768

- binhduong@vetta.com.vn

- Xem bản đồ